About TDC

Established in 1986, Tendency's main products are divided into the following categories: Residential Hinges, Commercial Hinges with ANS! / BHMA certificate, Spring Hinges with UL certificate, Stainless Steel Hinges with CE certificate. Tendency is not only passed 1S09001 Quality System but also qualified by International Authoritative Attestation.

Tendency is with professional manufacturing line as well as strong quality control system, the company is equipped with stamping, polishing, plating and assembling production lines, operated by experienced technical personnel and has excellent manaqement team. Tendency always insists on reasonable price, high quality products and excellent services. We are always prepared to develop with customers to win mutual prosperity.

-

200

MILLION+

Products Sold

Worldwide -

30

Years

Leading Hinge

Innovation -

40

MILLION+

Doors Stabilized

Globally -

140

Available In 148

Countries -

No.1

Door Hinges Brand

on Amazon -

OEM

supplier of STANLEY

HINGES and HAGER.

company history

TDC established its manufacturing facility in Pinghu, marking the beginning of its operations.

the company expanded into trading with the founding of TDC Trading Company in Pinghu.

TDC further extended its commercial network by establishing the Shanghai TDC Trading Company.

the company continued its expansion with the launch of the Guangzhou TDC Trading Company.

Increase profitability and quality by upgrading your anodizing process with us.

Thinner coatings

Compared to other coating methods, the anodizing process establishes thinner coats on the surface of the substrate. This quality makes it useful for use on precision machined parts, as the coating thickness does significantly affect part size.

Longer lasting color

As materials that undergo the dyed anodizing process display long-lasting color that is highly resistant to UV radiation and fading, they are ideal for use in outdoor applications.

Smaller environmental impact

With advanced sewage system, waste water generated from the anodizing production process is treated as clean as possible. Additionally, we use environmentally friendly chemicals.

Higher durability

Anodized surfaces display exceptional hardness and abrasion resistance, especially when compared to paint and powder coats. Anodized material is less likely to scratch, chip, or flake, resulting in much longer service life.

Greater corrosion resistance

Anodized surfaces are highly corrosion resistant, making them particularly useful for applications regularly exposed to water, salt spray, and other corrosive substances.

Lower cost

The price of anodizing metals is on par with other coating processes, such as painting and powder coating. The enhanced durability of the anodized finish ensures a longer component lifetime, thereby reducing the cost of maintenance.

Feel The Value Stream In TDC Production

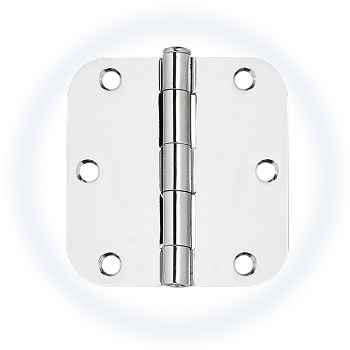

Raw Material of Stainless Steel

Value: Stable properties, suitable for bending and forming

Selecting the materials of materials cost

Most products use Q195. If the material hardness requirements and functional test requirements are high, Q235 is selected, and if the corrosion resistance (such as humidity, food contact environment) or the surface is smooth and shiny, the stainless steel material is selected.

Stamping Process

Value: Multiple stamped lines for 30% efficiency up

Stamp on stainless steel small sheet to get hinge parts. Stamped hinges offer high quality, precision, and at lower cost than machined or extruded hinges, due to the efficiencies of progressive die metal stamping.

Piercing Process

Value: Precise and quick process

Cutting holes in hinge through press machines.

Anodizing Process

Value: 20% finishing cost lower & 30% surface effect up

Our hinges are anodized through advanced automated equipment by our professional team. Quality and stable anodizing finish is one of our advantages comparing to our competitors.

Automatic Assembly

Value: Save 10% on labor cost and 10% Improvement in quality

Automated assembly machines responsible for multiple set of hinges at a time. No extra labors needed and highly under controlled.

Quality Inspection of Semi-product

Value: Keeps semi-products under quality standard

100% inspecting the finish, the cup, the holes, the pumps and the sharp edge whether they are passed for next operations.

Innovative Packaging

Here’s something new invented by Maxave. With our creative boxing methods that utilize the max room of regular box, we save shipping cost and improve shipping efficiency.

Value: 20% packaging room saved & 5% shipping cost cut

-

Raw Material Control

What values do you look for in a company? The following values are at the heart of our company DNA. They guide the way that we work with our clients and with each other at every level of our organisation. These values represent the foundations for creating wonderful furniture hardware. Material control procedures also allow for effective raw material traceability which is essential for guaranteeing product quality and performance claims. We have a close rapport with our preferred suppliers who understand our quality requirements and work with us to assure materials meet our high standards.

-

Manufacturing Control

Manufacturing procedures are established for each individual product. Throughout the manufacturing and packaging stages there are in-process checks to make sure all products are being manufactured to meet specified parameters. Standard Operating Procedures govern each manufacturing operation and are routinely reviewed to maximize efficiency while maintaining quality. Line clearances and room clean up are done at the conclusion of each run, to keep each patch of products are under good preservation.

Keep Everything on Track

-

Connecting 100+ Local Suppliers

Built on a good local presence, we connect with our supply chain with end-to-end support across — strategy and process, platforms and technology, and intelligence, insight & expertise. With 100+ suppliers in our supply chain, together with our own factories, we have the most versatile product ranges as well as product variants. No more worrying about multiple orders and rare types. Leverage our deep expertise and holistic solutions to deliver on your furniture hardware. -

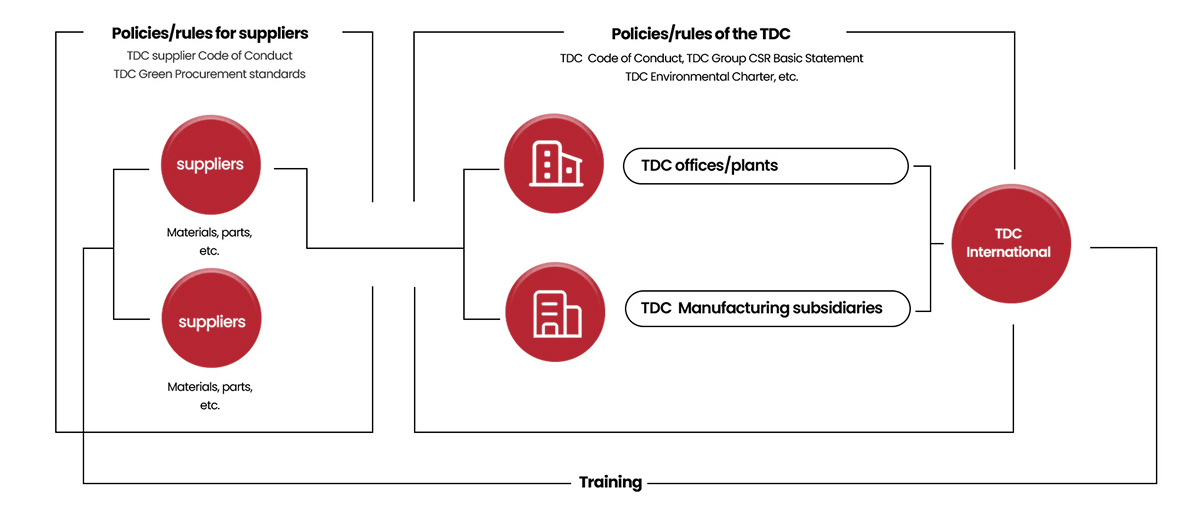

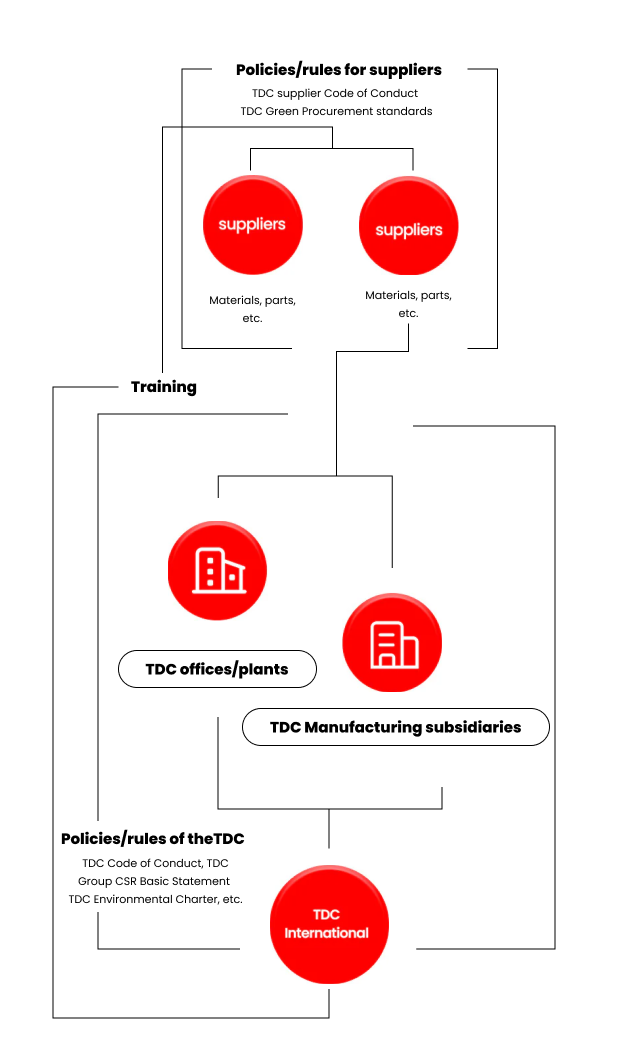

Supply Chain-Related Policies

All TDC production sites are required to adhere to various TDC policies covering matters such as the environment, legal compliance, procurement and security. These policies include TDC Code of Conduct, TDCp CSR Basic Statement, and TDC Environmental Charter, etc. We publish the code to all our suppliers to make it widely known in daily processing.

To Provide You with Better Service

Contact

Tel: +8613325838282

Add: 6265 Providence Way Eastvale,CA 92880