Choosing the Right Heavy Duty Hinges for Your Heavy Doors: Key Features to Consider

Choosing the Right Heavy Duty Hinges for Your Heavy Doors: Key Features to Consider

Hinge strength determines the reliability of heavy duty hinges for heavy doors. Strong hinges prevent sagging and misalignment. They support the door’s weight and ensure safe operation. Builders prioritize hinge load ratings to maintain durability and avoid frequent repairs. Proper hinge selection protects property and keeps users safe every day.

Heavy Duty Hinges for Heavy Doors: Key Considerations

Assessing Door Weight and Size

Every door has a unique weight and size. These two factors play a major role in choosing the right hinge. Large doors often weigh more and need stronger support. Builders measure the door’s height, width, and thickness before selecting hinges. They use these measurements to estimate the total weight.

Tip: Always check the manufacturer’s specifications for the door. This information helps avoid mistakes during hinge selection.

A heavy door puts extra stress on its hinges. If the hinge cannot handle the load, the door may sag or become misaligned. This can lead to safety risks and costly repairs. For this reason, experts recommend using at least three hinges for tall or wide doors. Some doors may need four or more hinges for extra support.

A simple checklist for assessing door weight and size:

Measure the door’s height, width, and thickness.

Find the door’s total weight.

Check if the door has glass panels or metal reinforcements.

Decide how many hinges the door needs based on its size.

Matching the hinge strength to the door’s weight and size ensures smooth operation. It also extends the life of both the door and the hinges.

Importance of Hinge Load Rating

The hinge load rating shows how much weight a hinge can support. Manufacturers test heavy duty hinges for heavy doors to determine this rating. Builders must compare the door’s weight to the hinge’s load rating before installation.

If the hinge load rating is too low, the door may sag or fail. This can cause injuries or property damage. Choosing a hinge with a higher load rating prevents these problems. It also keeps the door working smoothly for years.

A table can help compare hinge load ratings:

Door Weight (lbs) | Recommended Hinge Load Rating (lbs per hinge) | Number of Hinges Needed |

|---|---|---|

100-200 | 50-75 | 3 |

200-400 | 75-150 | 3-4 |

400+ | 150+ | 4+ |

Note: Always use the highest load rating available for very heavy doors.

Proper hinge selection prevents sagging and ensures durability. Heavy duty hinges for heavy doors must match or exceed the door’s weight. This step protects the door, the frame, and the people who use it.

Hinge Material and Finish

Best Materials for Strength

Manufacturers use strong materials to make heavy duty hinges for heavy doors. Steel stands out as the most common choice. It offers high strength and resists bending under heavy loads. Stainless steel provides even more durability and works well in both indoor and outdoor settings. Brass also appears in some hinges. It gives a classic look and resists wear, but it does not match steel for strength.

A quick comparison of common hinge materials:

Material | Strength | Durability | Common Use |

|---|---|---|---|

Steel | High | High | Interior/Exterior |

Stainless Steel | Very High | Very High | Exterior/Marine |

Brass | Medium | High | Decorative Doors |

Tip: For the heaviest doors, choose stainless steel or high-grade steel hinges.

Corrosion Resistance and Finish

Corrosion can weaken hinges over time. Stainless steel resists rust and works well in humid or coastal areas. Some steel hinges have special coatings, like zinc plating or powder coating, to block moisture and prevent rust. Brass resists corrosion but may tarnish if not polished.

Finishes also affect appearance and maintenance. Satin, polished, or matte finishes help match the hinge to the door’s style. Builders select finishes that blend with the door and protect the hinge from scratches.

Note: Always check the environment before choosing a hinge finish. Wet or salty air needs extra protection for heavy duty hinges for heavy doors.

Hinge Types for Heavy Doors

Butt, Continuous, and Piano Hinges

Different hinge types offer unique benefits for heavy doors. Butt hinges remain the most common choice. They feature two rectangular leaves that attach to the door and frame. Builders use them for both residential and commercial doors. Butt hinges provide strong support and allow the door to swing smoothly.

Continuous hinges, also called piano hinges, run the full length of the door. These hinges distribute weight evenly. They work well for doors that see frequent use or need extra stability. Piano hinges prevent warping and reduce stress on the door material.

Some projects require specialty hinges. For example, pivot hinges support doors from the top and bottom. These hinges suit very large or thick doors. Builders select the hinge type based on the door’s size, weight, and function.

Tip: Continuous hinges often last longer on high-traffic doors because they spread the load across the entire edge.

Choosing the Right Type

Selecting the right hinge type depends on several factors. Builders consider the door’s weight, thickness, and how often people will use it. Butt hinges fit most standard heavy doors. Continuous hinges work best for oversized or extra-heavy doors. Pivot hinges help with doors that need to swing both ways or have unique mounting needs.

A quick comparison helps clarify the differences:

Hinge Type | Best For | Key Benefit |

|---|---|---|

Butt | Standard heavy doors | Simple installation |

Continuous | Oversized/heavy doors | Even weight support |

Pivot | Extra-large doors | Top/bottom support |

Heavy duty hinges for heavy doors require careful selection. The right hinge type ensures safety, smooth operation, and long-lasting performance.

Hinge Size and Door Thickness

Measuring for Proper Fit

Accurate measurements help ensure that heavy duty hinges fit the door and frame correctly. Builders start by measuring the door’s thickness with a tape measure. They record the width of the door edge where the hinge will attach. Next, they measure the height of the door. These measurements help determine the correct hinge size and placement.

Tip: Always measure both the door and the frame. Small differences can affect how the hinge fits and operates.

A door that is too thick or too thin for the chosen hinge may not open or close smoothly. Proper fit also prevents stress on the hinge pins and screws. Builders check the manufacturer’s recommendations for minimum and maximum door thickness for each hinge model.

Selecting Hinge Dimensions

Hinge dimensions must match the door’s size and weight. Standard heavy duty hinges range from 4 inches to 6 inches in height. Thicker or taller doors often need larger hinges for extra support. The width of the hinge leaf should cover enough of the door edge to provide stability.

A quick reference table helps with hinge selection:

Door Thickness | Recommended Hinge Height |

|---|---|

1-3/8" | 4" |

1-3/4" | 4.5" – 5" |

2" or more | 5" – 6" |

Builders also consider the number of hinges. Heavier or taller doors may need four or more hinges to distribute weight evenly. Correct hinge size and placement keep the door aligned and extend the life of both the door and the hardware.

Installation Factors

Screw and Mounting Choices

Correct screws and mounting methods play a key role in hinge performance. Builders select screws that match the hinge material and door weight. Heavy duty hinges for heavy doors require long, thick screws. These screws anchor the hinge deep into the door and frame. Short or weak screws can loosen over time and cause the door to sag.

A quick checklist for screw selection:

Use steel or stainless steel screws for strength.

Choose screws at least 1.5 inches long for heavy doors.

Match the screw head to the hinge holes (flat or countersunk).

Tip: Builders often use all the screw holes in each hinge. This practice spreads the load and increases stability.

Some doors, such as fire-rated or security doors, need special mounting hardware. In these cases, professional installation ensures the right hardware and methods.

Alignment and Smooth Operation

Proper alignment keeps the door moving smoothly. Builders mark the hinge positions carefully before drilling. They use a level to check that each hinge sits straight. Misaligned hinges can cause the door to bind or scrape.

A table for common alignment checks:

Step | Purpose |

|---|---|

Mark hinge spots | Ensures even spacing |

Use a level | Keeps hinges straight |

Test door movement | Checks smooth swing |

Note: Large or extra-heavy doors often need two people for safe installation. Professional installers have the tools and experience to handle these jobs.

Correct installation protects the door, the frame, and the people who use the door every day.

Extra Features and Maintenance

Ball Bearing Hinges

Ball bearing hinges offer a major upgrade for heavy duty doors. These hinges use small steel balls between the hinge knuckles. The balls reduce friction and help the door swing smoothly. Builders often choose ball bearing hinges for doors that see frequent use. The design also helps prevent squeaking and wear.

A quick comparison shows the benefits:

Feature | Standard Hinge | Ball Bearing Hinge |

|---|---|---|

Smooth Operation | Moderate | Excellent |

Noise Reduction | Low | High |

Durability | Good | Superior |

Tip: Ball bearing hinges work best for commercial buildings, schools, and hospitals. These places have doors that open and close many times each day.

Security and Upkeep

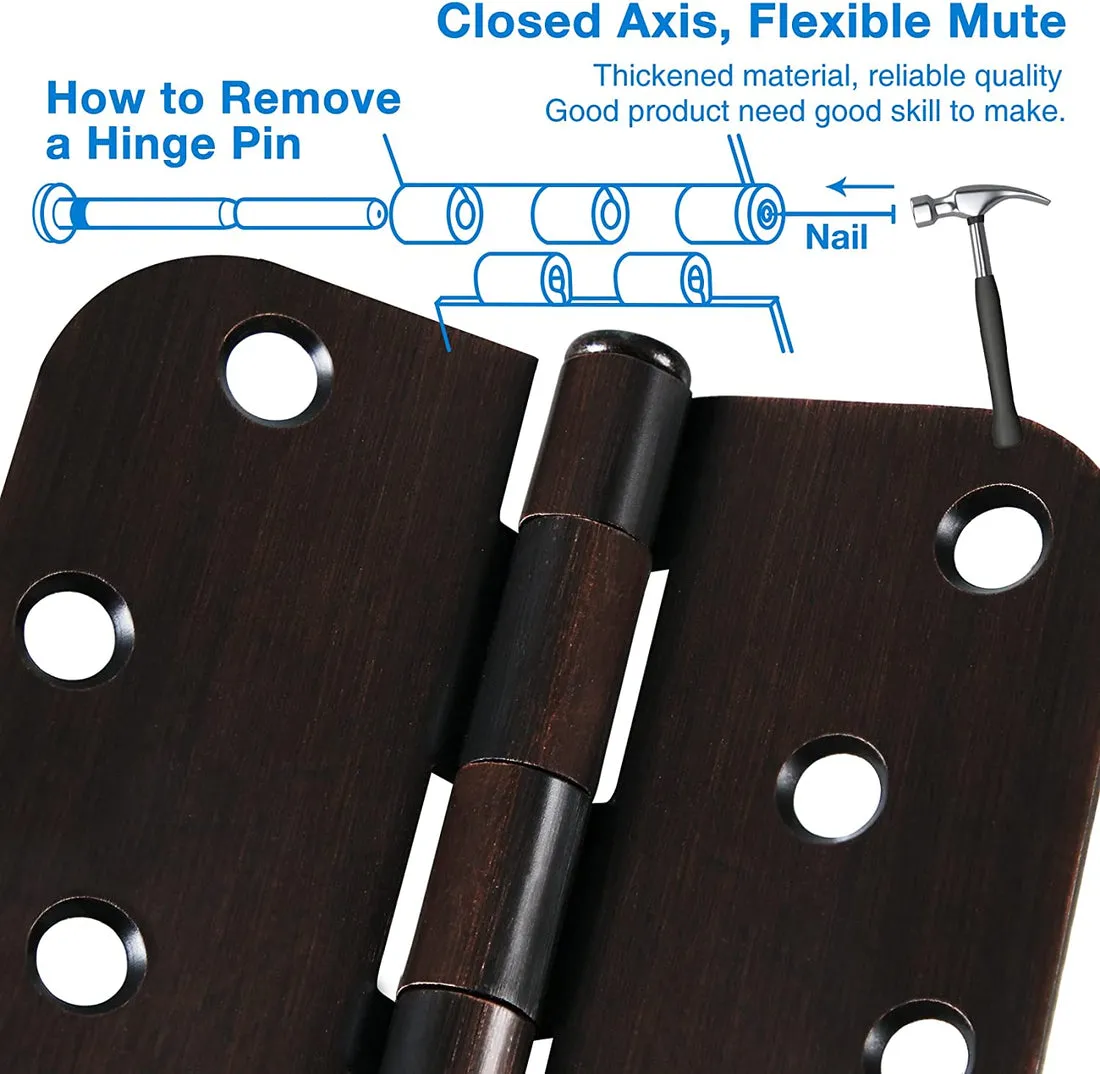

Security matters for heavy doors. Some heavy duty hinges include non-removable pins or security studs. These features stop intruders from removing the hinge and gaining entry. Builders should check for these options when selecting hinges for exterior or high-security doors.

Proper maintenance keeps hinges working well. Regularly check for loose screws or signs of rust. Apply a small amount of lubricant to the hinge pins if the door starts to squeak. Clean the hinges with a damp cloth to remove dust and debris.

A simple maintenance checklist:

Inspect hinges every few months

Tighten loose screws

Lubricate moving parts

Clean off dirt and grime

Regular care extends the life of heavy duty hinges and keeps doors safe and easy to use.

Common Mistakes to Avoid

Underestimating Door Weight

Many builders make the mistake of guessing a door’s weight. This error leads to hinge failure and door misalignment. Heavy doors need accurate measurements. A bathroom door does not weigh the same as a solid wood entry door. Builders should always use a scale or check the manufacturer’s specifications.

Tip: Always round up when estimating door weight. Extra support prevents future problems.

A door that weighs more than expected can cause the hinges to bend or break. This mistake often results in costly repairs. Builders should remember that glass panels, metal reinforcements, or decorative features add extra weight. They should include these factors in their calculations.

A quick checklist helps avoid this mistake:

Weigh the door or check specifications.

Add weight for glass or metal parts.

Choose hinges with a higher load rating than needed.

Ignoring Environmental Factors

Some builders forget to consider the environment where the door will be used. Humidity, rain, and salty air can damage hinges over time. Stainless steel or coated hinges resist rust in wet or coastal areas. Brass may tarnish in damp conditions.

A table can help match hinge material to the environment:

Environment | Best Hinge Material |

|---|---|

Humid/Coastal | Stainless Steel |

Dry/Indoor | Steel or Brass |

Industrial | Coated Steel |

Note: Builders should always check the location before choosing hinge material and finish.

Ignoring these factors can shorten hinge life and reduce door safety. Careful planning ensures the right hinge lasts for years.

Selecting heavy duty hinges for heavy doors involves measuring door weight, choosing the right material, and matching hinge type. Builders check hinge size and install with proper screws. Regular maintenance keeps doors safe.

Use this checklist to ensure safety and durability with every installation.

FAQ

How many heavy duty hinges does a heavy door need?

Most heavy doors need at least three hinges. Extra-tall or wide doors may need four or more for better support and stability.

What is the best way to maintain heavy duty hinges?

Regularly check for loose screws, clean off dirt, and apply lubricant to moving parts. This routine keeps hinges working smoothly and extends their lifespan.

Can heavy duty hinges be used outdoors?

Yes. Stainless steel or coated steel hinges resist rust and work well outdoors. Builders should always choose corrosion-resistant materials for exterior doors.

Related articles

-

Choosing the Right Interior Door Hinges

Find the best interior door hinges for your space by considering door weight, style, material, and compatibility for smooth, secure operation.Dec-12-2025 Learn More >> -

The Role of Security Door Hinges in Enhancing Home Safety

Security door hinges boost home safety by preventing forced entry and tampering, using strong materials and tamper-resistant designs.Dec-12-2025 Learn More >> -

Exploring the Versatile Types of Hinges for Every Application

Types of hinges range from butt and piano to concealed and strap, each suited for specific doors, cabinets, and gates to ensure durability and style.Dec-12-2025 Learn More >> -

The aesthetic appeal of black cabinet hinges

Black cabinet hinges add bold contrast, elegance, and durability to any cabinetry, suiting both modern and traditional styles for a timeless upgrade.Dec-12-2025 Learn More >>

To Provide You with Better Service

Contact

Tel: +8613325838282

Add: 6265 Providence Way Eastvale,CA 92880