A Complete Guide to Hinge Types for Modern Projects

A Complete Guide to Hinge Types for Modern Projects

Selecting the right hinge types shapes both the function and the look of doors and cabinets. In commercial settings, cabinet hinges face heavy use, so durability matters.

The answer lies in hinge selection, a critical choice that impacts both function and visual appeal.

Attention to installation, material, and long-term strength ensures lasting results.

Overview of Hinge Types

Selecting the right hinge types is essential for both residential and commercial projects. Each hinge design offers unique features that suit specific functions and styles. The table below summarizes the most common hinge types, their appearance, structure, and typical uses:

Hinge Type | Appearance/Structure | Typical Applications | Key Function |

|---|---|---|---|

Butt Hinges | Rectangular plates with a central pin | Doors, cabinets, furniture | Smooth swinging motion |

Concealed Hinges | Hidden when installed, minimalist look | Modern cabinetry, interior doors | Sleek, unobtrusive operation |

Continuous Hinges | Long, narrow, runs full length of door/lid | High-traffic doors, toolboxes, partitions | Uniform support, smooth operation |

Strap Hinges | Elongated, decorative plates | Gates, barn doors, chests | Structural support, decorative appeal |

Pivot Hinges | Central pivot point, often hidden | Heavy doors, high-traffic areas | Supports heavy loads, allows bidirectional swing |

Butt Hinges

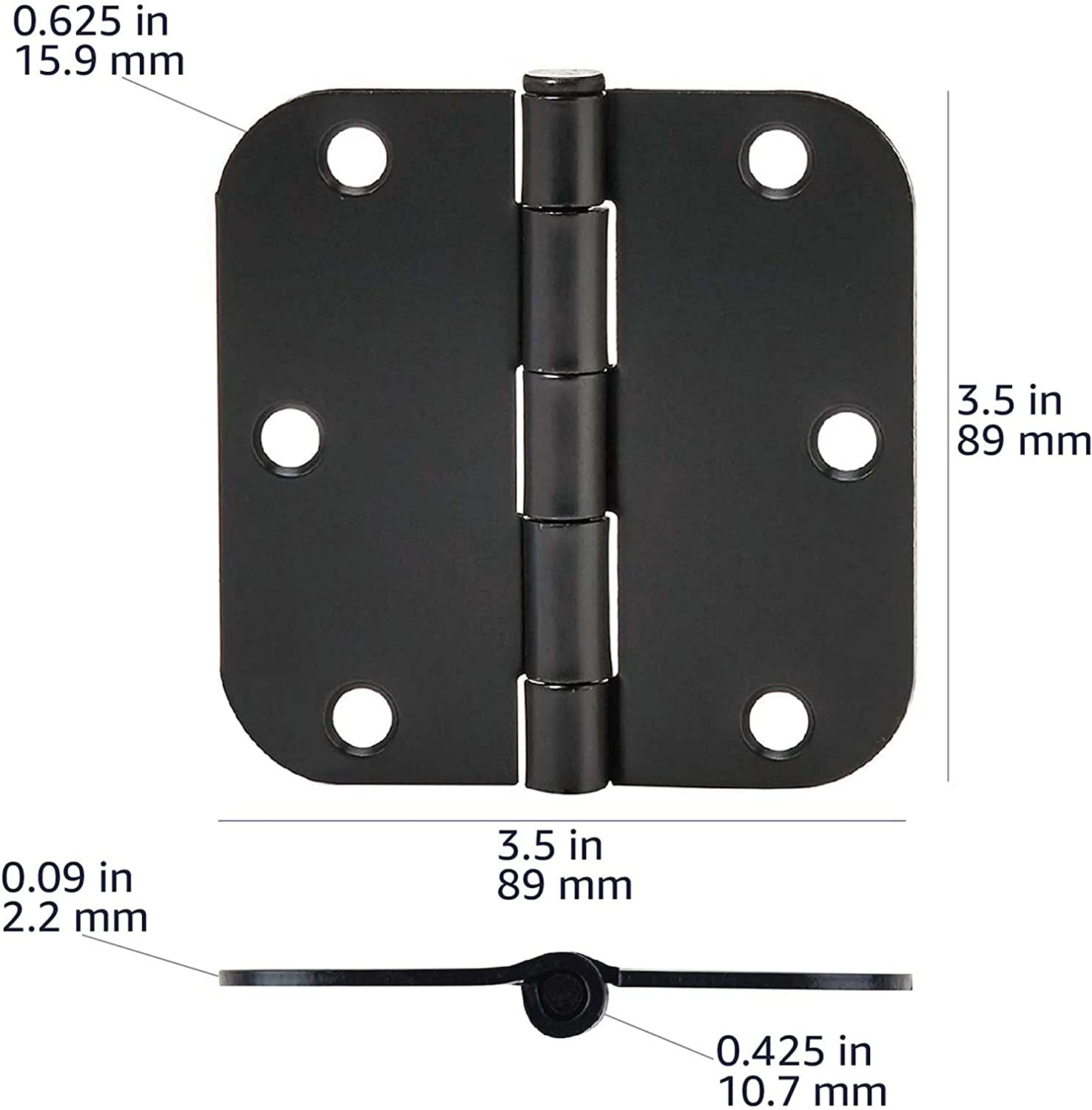

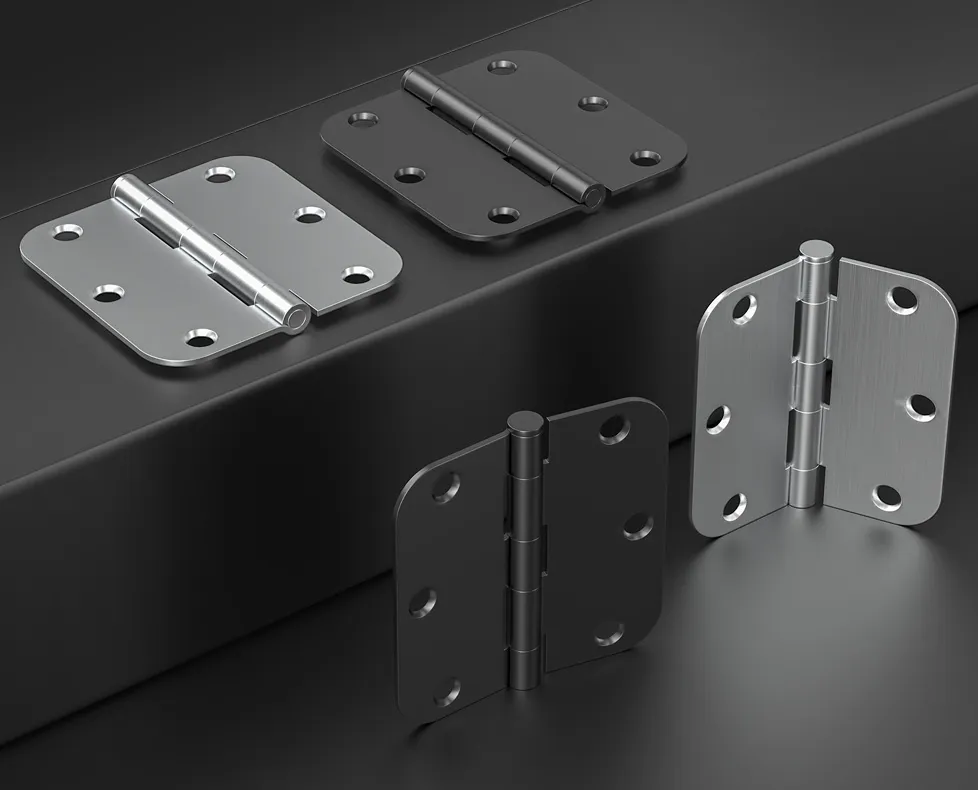

Butt hinges remain one of the most widely used hinge types in both homes and businesses. These hinges feature two rectangular metal plates joined by a central pin, resembling a butterfly when open. They offer a simple yet robust design that supports doors, cabinets, and furniture.

Butt hinges provide strong support and can handle heavy doors.

Installation is straightforward, requiring only basic tools.

Their visible placement can make them a target for tampering, especially on exterior doors.

Over time, butt hinges may loosen and need regular maintenance.

Tip: Butt hinges work best for interior and exterior doors where strength and reliability matter most.

Concealed Hinges

Concealed hinges, sometimes called European hinges, stay hidden from view when the door is closed. This design creates a clean, modern appearance that fits well with contemporary interiors.

These hinges are popular in kitchens, bathrooms, and modern furniture.

Concealed hinges enhance security because they are not accessible from the outside.

They require precise installation and may not support as much weight as butt hinges.

Maintenance needs are generally low, making them a practical choice for busy households.

Concealed hinges suit projects where aesthetics and a seamless look take priority.

Continuous Hinges

Continuous hinges, also known as piano hinges, run the entire length of a door or lid. This design distributes weight evenly and provides consistent support.

Common in commercial and industrial settings, continuous hinges appear on high-traffic doors, toolboxes, and folding partitions.

They offer increased durability and security, especially for heavy or frequently used doors.

Industries such as aerospace, marine, and electronics rely on continuous hinges for their reliability and resistance to harsh conditions.

Note: Continuous hinges help prevent sagging and extend the lifespan of doors in demanding environments.

Strap Hinges

Strap hinges combine structural support with decorative appeal. Their elongated plates, often crafted from wrought iron or stainless steel, add character to gates, barn doors, and large chests.

Strap hinges stabilize heavy doors and gates, ensuring smooth operation.

They come in various styles and finishes, allowing designers to match different architectural themes.

Both traditional and modern projects benefit from the unique look and strength of strap hinges.

Strap hinges serve as both a functional and aesthetic element in many architectural designs.

Pivot Hinges

Pivot hinges use a central pivot point, allowing doors to swing smoothly and support substantial weight. These hinges often remain hidden, contributing to a modern, streamlined appearance.

Pivot hinges excel in high-traffic areas like restaurants and commercial buildings.

They support doors weighing over 1,000 pounds, reducing stress on the frame and preventing sagging.

Some pivot hinges allow doors to open in both directions, improving accessibility.

Their durable construction ensures a long service life, even in demanding environments.

Pivot hinges offer versatility and strength, making them ideal for heavy-duty and modern applications.

By understanding the unique features and uses of these hinge types, project planners can select the best option for their specific needs.

Features & Uses

Load Capacity

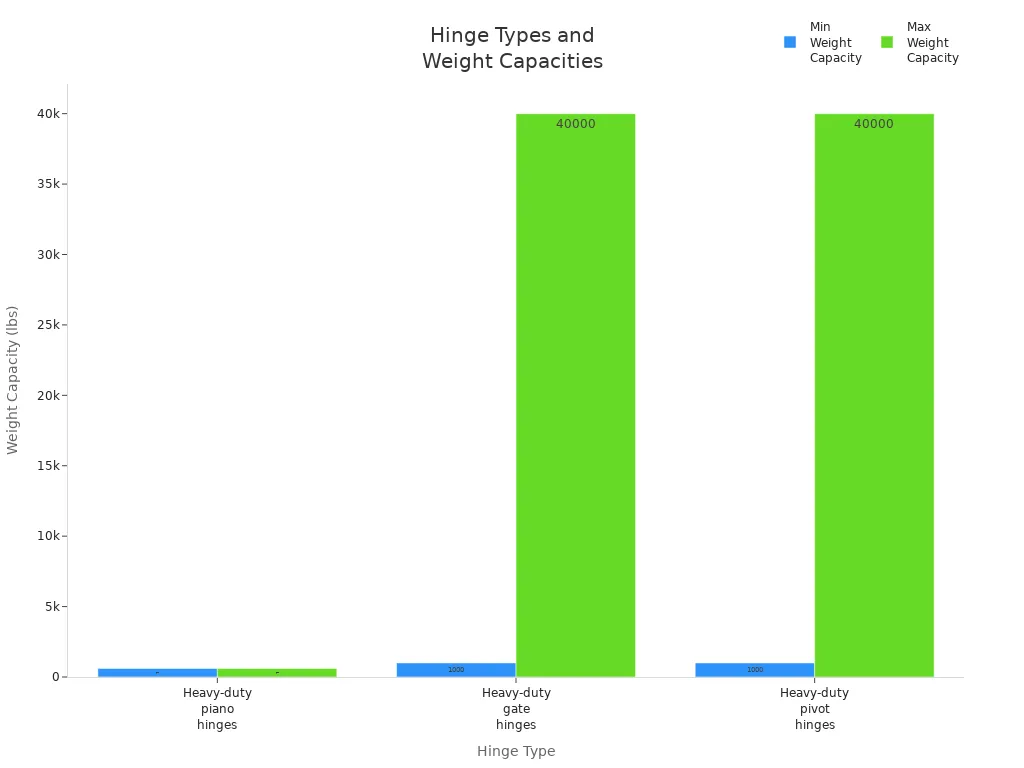

The strength of a hinge determines how much weight it can support. Heavy-duty piano hinges often hold up to 600 pounds. Gate and pivot hinges can carry loads between 1,000 and 40,000 pounds. These hinges use materials like stainless steel, steel, and aluminum for maximum durability.

Hinge Type | Weight Capacity (lbs) | Material Options |

|---|---|---|

Heavy-duty piano hinges | Up to 600 | Stainless steel, steel, aluminum |

Heavy-duty gate hinges | 1,000 to 40,000 | Carbon steel, stainless steel |

Heavy-duty pivot hinges | 1,000 to 40,000 | Various industrial materials |

Heavy-duty hinges stabilize large doors, gates, or lids. Their robust construction allows them to handle significant weight in demanding environments.

Range of Motion

Different hinge types provide unique movement options.

Butt hinges allow doors to swing in one direction.

Pivot hinges enable doors to swing both ways, increasing accessibility.

Continuous hinges offer smooth, consistent movement along the entire length of a door or lid.

Understanding the required range of motion helps users select the right hinge for doors, cabinets, or machinery.

Common Applications

Hinge types serve many purposes in homes, offices, and industries. The table below shows where each hinge works best:

Hinge Type | Visibility | Installation | Applications |

|---|---|---|---|

European Hinge | Concealed | Mortised | Kitchen cabinets, bathroom cabinets, office cabinets, wall-mounted cabinets |

Barrel Hinge | Semi-concealed | Surface-mounted or mortised | Furniture cabinets, media equipment cabinets, curio display cabinets |

Butt Hinge | Exposed or Partially Concealed | Mortised | Kitchen and bathroom cabinets, display cabinets |

Pin Hinge | Exposed or Partially Concealed | Surface Mounted or Mortised | Cabinet doors, interior and exterior doors |

Concealed Hinges | Completely Hidden | Adjustable | Modern kitchen cabinets, high-end furniture, built-in closets |

Heavy-Duty Hinges | Not specified | Not specified | Industrial and commercial applications, warehouses, factories |

Designers and builders choose hinge types based on the weight, movement, and location of the door or cabinet. This careful selection ensures safety and long-lasting performance.

Materials & Finishes

Metal Options

Choosing the right metal for hinges affects both strength and cost. The table below compares popular hinge materials:

Material | Strength | Finish Options | Corrosion Resistance | Best Use Case |

|---|---|---|---|---|

Solid Brass | High | Extensive | Moderate | Stylish interior/exterior doors |

Stainless Steel | Very High | Limited | Excellent | High-traffic and moist areas |

Steel | Very High | Limited | Moderate | Commercial and heavy-load doors |

Aluminum | Low to Moderate | Limited | Good | Lightweight, interior doors |

Stainless steel stands out for its strength and durability, but it usually costs more. Brass hinges offer a classic look and last long, though they tend to be pricier than steel. Aluminum works well for lightweight doors and costs less, while zinc alloy provides affordability but less durability.

Corrosion Resistance

Hinges often face moisture, especially in kitchens, bathrooms, or outdoor spaces. Stainless steel resists rust and corrosion better than most metals. Grade 304 stainless steel fits indoor or mild outdoor use. Grade 316 stainless steel performs best in coastal or marine environments, where saltwater exposure is common. Marine hinges made from these grades protect against harsh weather and humidity.

Tip: For outdoor or high-humidity projects, select hinges made from 316 stainless steel for maximum longevity.

Matching Style

Hinge finishes influence both appearance and durability. Common options include:

Plated finishes: Add shine and improve corrosion resistance with materials like zinc, nickel, or chrome.

Powder coated finishes: Provide a uniform color and resist chipping, scratching, and fading.

Living finishes: Develop a patina over time, giving each hinge a unique character.

Designers often match hinge finishes to door hardware or room décor. The right finish can blend hinges into the background or make them a standout feature.

Installation Tips

Surface vs. Mortise Mount

Choosing between surface and mortise mounting depends on the project’s needs and the hinge types selected. The table below highlights the main differences:

Feature | Mortise Hinge | Surface Hinge |

|---|---|---|

Installation Process | Requires marking, routing, and cutting mortise pockets | Simple attachment to surfaces with screws |

Design Characteristics | Recessed, only the barrel is visible when closed | Both leaves visible on the door or frame |

Performance Specifications | Heavy-duty, ideal for high-traffic and heavy loads | Flexible, efficient for retrofits and light use |

Mortise mounting offers a flush, professional look but needs more skill and preparation. Surface mounting works well for quick installations and retrofits.

Tools Needed

Accurate installation starts with the right tools. Essential items include:

Screwdriver or drill with screwdriver bit

Tape measure for precise measurements

Level to ensure proper alignment

Wood shims for adjustments

Pencil for marking positions

Chisel and hammer for mortise hinges

Wood screws matched to hinge material

A door hinge jig helps create perfect mortises, ensuring hinges sit flush and operate smoothly.

Mistakes to Avoid

Installers often make errors that affect performance and durability. Common mistakes include:

Misalignment: Failing to measure and level leads to uneven gaps and sticking doors.

Wrong hinge type: Using the incorrect hinge for the door or cabinet causes poor fit and function.

Incorrect screws: Using short or mismatched screws can cause hinges to fail or corrode.

Careful planning, accurate measurements, and the right tools help avoid these issues and ensure a secure, long-lasting installation.

Choosing Hinge Types

Assessing Project Needs

Selecting the right hinge for a project starts with a careful assessment of the requirements. The weight and size of the door or panel play a major role in this decision. Heavier doors need stronger hinges, while lighter doors can use smaller or less robust options. The material of the hinge should match the environment and budget. For example, stainless steel works well in areas with high moisture, while zinc-plated hinges offer a cost-effective solution for dry, indoor spaces. The intended use of the door or cabinet also matters. High-traffic areas, such as commercial entrances, require hinges that can withstand frequent use and provide security.

Project planners should always match the hinge type to the specific needs of the application to ensure smooth operation and long-lasting performance.

The following table summarizes the main criteria for assessing project needs:

Criteria | Description |

|---|---|

Load-Bearing Capacity | Match the hinge type with the weight of the door or gate it will support. |

Material and Durability | Consider materials like stainless steel for corrosion resistance or zinc-plated for budget options. |

Intended Use and Aesthetics | Understand the application (commercial vs. residential) and choose a style that fits the project. |

Environment & Usage

Environmental conditions have a direct impact on hinge performance and lifespan. Moisture, temperature changes, dust, and chemicals can all affect how well a hinge works over time. For outdoor or humid environments, stainless steel or polymer hinges provide excellent corrosion resistance. In areas exposed to chemicals or saltwater, sealed or gasketed hinges offer extra protection. High-temperature alloys are best for locations with extreme heat.

Temperature

Humidity

Exposure to dust or chemicals

Outdoor usage

When selecting a hinge, consider the following:

Moisture and humidity levels

Exposure to saltwater or chemicals

Operating temperature range

Vibration and mechanical stress

The material used in the hinge affects its durability, corrosion resistance, and load capacity. For example, marine-grade stainless steel resists rust in coastal areas, while powder-coated finishes protect against scratches and fading.

Function vs. Aesthetics

Every project must balance function and appearance. Hidden hinges improve the look of cabinets and doors by removing visible hardware. These hinges create a clean, modern appearance but often cost more and require precise installation. Visible hinges, such as butt or strap hinges, are easier to install and usually cost less. However, they can stand out and affect the overall design.

Hidden hinges enhance aesthetics by eliminating bulky hardware.

They are often more complex and costly to manufacture.

Visible hinges are easier to install and more cost-effective, but may detract from design.

Designers must decide if the project needs a seamless look or if visible hardware fits the style. In some cases, decorative hinges add character and become a feature of the design.

Quick Checklist for Selecting Hinge Types

A step-by-step checklist helps ensure the right hinge types are chosen for any project:

Identify the cabinet or door type.

Determine the door mounting style (overlay, inset, or partial overlay).

Choose the hinge type based on both function and appearance.

Select desired features, such as soft-close or self-closing mechanisms.

Determine the required opening angle.

Check all physical specifications, especially when replacing existing hinges.

🛠️ Tip: For high-traffic doors, ball-bearing and continuous hinges provide the best durability and smooth operation. Heavy-duty commercial hinges also work well in busy environments.

Careful planning and attention to these steps help builders and designers select hinge types that deliver both performance and style.

Maintenance Guide

Cleaning & Lubrication

Regular cleaning and lubrication keep hinges working smoothly and extend their lifespan. Dirt, dust, and moisture can build up on hinge surfaces, leading to squeaks or even rust. To maintain hinges, follow these steps:

Remove the hinge if possible for a thorough cleaning.

Wipe the hinge with a damp cloth. Use mild soap for stubborn grime.

Scrub away rust with steel wool or a small brush. Apply rust remover if needed.

Dry the hinge completely and reassemble it, tightening all screws.

Clean the hinge pin and joints before applying lubricant.

Use a small amount of lubricant, such as silicone spray for most hinges or lithium grease for heavy-duty types.

Open and close the door several times to distribute the lubricant.

Wipe off any excess to prevent buildup.

💡 Tip: WD-40 works well for loosening stiff hinges but does not provide long-term lubrication.

Inspecting for Wear

Routine inspections help catch problems early and prevent costly repairs. Most experts recommend checking hinges every few months, especially in high-use or harsh environments. Signs that a hinge needs attention include:

Squeaking or creaking sounds

Loose or missing screws

Rust or corrosion, especially in humid areas

Misalignment causing doors to sag or stick

Visible cracks, bends, or breaks

Regular maintenance prevents wear and tear, keeps doors operating safely, and extends the life of all hinge types. If a hinge shows repeated issues or severe damage, replacement ensures continued safety and performance.

Selecting the right hinge types ensures smoother operation, greater durability, and better aesthetics. Proper material and installation choices reduce maintenance. Regular inspection extends hinge life.

Improved function

Enhanced durability

Better appearance

Fewer repairs

A quick checklist helps users:

List project needs

Check weight and size

Decide on motion

Think about security

Consider environment

Choose type

Pick material and finish

Plan placement

Install and test

FAQ

What hinge type works best for heavy doors?

Steel pivot hinges support heavy doors. They provide stability and allow smooth movement. Builders often choose them for commercial entrances and large residential doors.

How often should someone lubricate hinges?

Most experts recommend lubricating hinges every six months. High-traffic areas may need more frequent attention. Regular lubrication prevents squeaks and extends hinge life.

Can a homeowner install concealed hinges without professional help?

Homeowners can install concealed hinges using basic tools. Precise measurements and careful alignment ensure proper function. Many manufacturers include instructions for easy installation.

Related articles

-

Exploring the Benefits of Double Spring Hinges for Commercial Spaces

Double spring hinge boosts commercial space safety, accessibility, and energy efficiency with automatic bidirectional door closing.Jan-15-2026 Learn More >> -

Choosing the Right Support for Your Gate Hinges

Find the best support on which gate hinges for your gate by matching hinge type, material, and installation to gate size and weight for lasting durability.Jan-15-2026 Learn More >> -

The Benefits of Choosing Iron Gate Hinges for Your Property

Iron gate hinges provide superior security, durability, and style, making them a smart investment for long-lasting property value.Jan-15-2026 Learn More >>

To Provide You with Better Service

Contact

Tel: +8613325838282

Add: 6265 Providence Way Eastvale,CA 92880