Everything You Need to Know About Hinges on Doors

Which hinges on door should someone choose for smooth, reliable operation? Many struggle with doors that squeak or sag, often due to poor hinge selection. The right hinge supports weight, boosts security with features like security studs, and offers style options. Heavy-duty materials also ensure durability and lasting performance.

Choosing Hinges on Door

Hinge Type by Door

Selecting the right hinge type depends on the door’s function, location, and design. Residential and commercial settings require different hinge solutions. Each hinge style offers unique benefits for specific applications.

Butt Hinge: This hinge appears most often in homes. It allows doors to swing open and closed smoothly.

Ball Bearing Hinge: Designed for heavy doors, this hinge reduces friction. High-traffic areas in commercial buildings benefit from its durability.

Concealed Hinge: Cabinet doors and modern interiors use concealed hinges for a clean, seamless look.

Spring-Loaded Butt Hinge: This hinge closes doors automatically. Both residential and commercial spaces use it for convenience and security.

Pivot or Paumelle Hinge: Lightweight interior doors often use pivot hinges. These hinges allow wide swings and easy movement.

Piano (Continuous) Hinge: Long or heavy panels require continuous support. Piano hinges provide stability along the entire length of the door.

TDC Strap Hinge: Rustic designs and gates feature strap hinges. Their decorative style suits barn doors and outdoor gates.

Offset Hinge: Historic renovations and accessibility upgrades use offset hinges. These hinges create wider openings for easier passage.

Tip: Always match the hinge type to the door’s intended use. For example, ball bearing hinges on door provide extra strength for heavy entryways, while concealed hinges suit modern cabinetry.

Matching Hinge to Door Weight

Door weight plays a critical role in hinge selection. Manufacturers recommend specific hinge sizes based on the door’s weight category. Choosing the correct hinge size ensures smooth operation and prevents sagging or misalignment.

Door Weight Category | Recommended Hinge Size | Application |

|---|---|---|

Light Weight Doors (Up to 200 lbs) | 3.5” to 4” hinges | Interior residential doors, lightweight cabinet doors |

Medium Weight Doors (200 lbs to 400 lbs) | 4.5” to 5” hinges | Exterior residential doors, interior commercial doors |

Heavy Weight Doors (Over 400 lbs) | 5” to 6” or larger hinges | Commercial doors, industrial applications |

Heavier doors require larger and more robust hinges. The number of hinges on door increases with height to distribute weight evenly. Accurate measurement of door weight helps prevent premature hinge failure.

Ball bearing hinges on door support both standard and heavy weights. Plain bearing hinges suit standard interior doors, while heavy-duty pivot hinges handle extreme loads in industrial settings. For example, heavy duty pivot hinges can support up to 40,000 pounds, making them suitable for specialized environments such as laboratories or manufacturing plants.

Note: Always check the manufacturer’s guidelines before installation. Using undersized hinges on door may lead to costly repairs and compromised security.

Why Hinge Selection Matters

Door Function and Longevity

Proper hinge selection ensures that doors operate smoothly and last longer. When installers choose the wrong hinge or fail to follow best practices, several problems can occur:

Installers must measure and position hinges precisely, using templates from manufacturers.

Clean, accurate mortises prevent stress on the door and frame.

Pre-drilling with the correct bit size helps screws hold firmly.

Reinforcement plates add strength in commercial settings.

Proper adjustment of reveals and clearances keeps doors aligned.

Regular lubrication reduces wear and tear.

If hinges on door do not match the door’s weight or size, users may notice sagging, drooping, or difficulty opening and closing. Overloaded hinges can even create safety hazards, such as falling cabinet doors or frequent replacements.

Security Impact

Hinges play a vital role in protecting both residential and commercial spaces. Commercial hinges often include features like non-removable pins and tamper resistance, making them suitable for high-risk environments. Residential hinges focus on basic safety, but higher-quality options can offer added protection. A strong hinge resists force, making it harder for intruders to break in. Quality hinges with non-removable pins prevent burglars from removing the door easily. When paired with a solid door and lock, hinges contribute significantly to overall security.

Tip: Upgrading to commercial-grade hinges can enhance security for homeowners seeking extra peace of mind.

Style and Appearance

Hinge style influences the overall look of a door. Modern trends favor hidden hinges for a seamless, minimalist appearance. These hinges blend with contemporary design themes and provide smooth movement. Pivot hinges add visual interest and dramatic motion, especially on large or heavy doors in minimalist spaces. Hidden hinges also improve durability and suit high-traffic areas, making them a popular choice for both function and style.

Types of Hinges on Door

Butt Hinges

Butt hinges remain the most common choice for both residential and commercial doors. Their design features two flat plates, or leaves, joined by a central pin. The following table outlines their defining features and typical applications:

Feature/Application | Description |

|---|---|

Leaf | Flat, rigid plate that attaches to doors or frames, providing stability and support. |

Leaf Width | Ensures optimal load distribution and smooth operation in heavy-duty installations. |

Leaf Length | Impacts hinge strength and weight-bearing capacity. |

Knuckle or Barrel | Houses the pin for pivotal movement, crucial for hinge operation. |

Applications | Used in homes, offices, industrial, medical, and marine settings. |

Heavy-Duty Applications | Essential for secure locations, transporters, and armored vehicles. |

Ball Bearing Hinges

Ball bearing hinges offer enhanced performance for high-traffic doors. They provide several advantages:

Hidden ball bearings reduce friction, resulting in smoother and quieter operation.

These hinges last two to three times longer than standard butt hinges.

Ball bearing hinges suit hospitals, schools, and other environments where durability is critical.

Spring Hinges

Spring hinges automatically close doors, making them ideal for energy efficiency and convenience. The table below compares spring hinges to standard hinges:

Aspect | Spring Hinges | Standard Hinges |

|---|---|---|

Automatic Closing | Yes, helps maintain indoor temperatures | No, requires manual closing |

Energy Efficiency | Reduces energy costs by preventing air escape | Less effective in energy savings |

Maintenance | Requires periodic adjustments for proper tension | Generally low maintenance |

Concealed Hinges

Concealed hinges remain hidden when the door closes, creating a seamless look. They offer:

Feature | Concealed Hinges | Traditional Hinges |

|---|---|---|

Adjustability | Vertical, horizontal, and depth adjustments | Limited or no adjustability |

Durability | Protected from environmental factors | More exposed, requires more maintenance |

Specialty Hinges

Specialty hinges address unique requirements in door hardware. The table below highlights several types and their applications:

Specialty Hinge Type | Unique Application |

|---|---|

Marine Hinges | Used on boats for storage hatches and doors, made of 316 Grade Stainless Steel. |

Wide Throw Hinges | Allow doors to swing a full 180 degrees, ideal for wide openings. |

Continuous Piano Hinges | Support heavy doors like piano lids and barn doors without sagging. |

Lift Off Hinges | Enable easy door removal for painting or moving large objects. |

Tip: Selecting the right hinges on door ensures optimal performance, safety, and longevity for any project.

Hinge Sizing and Placement

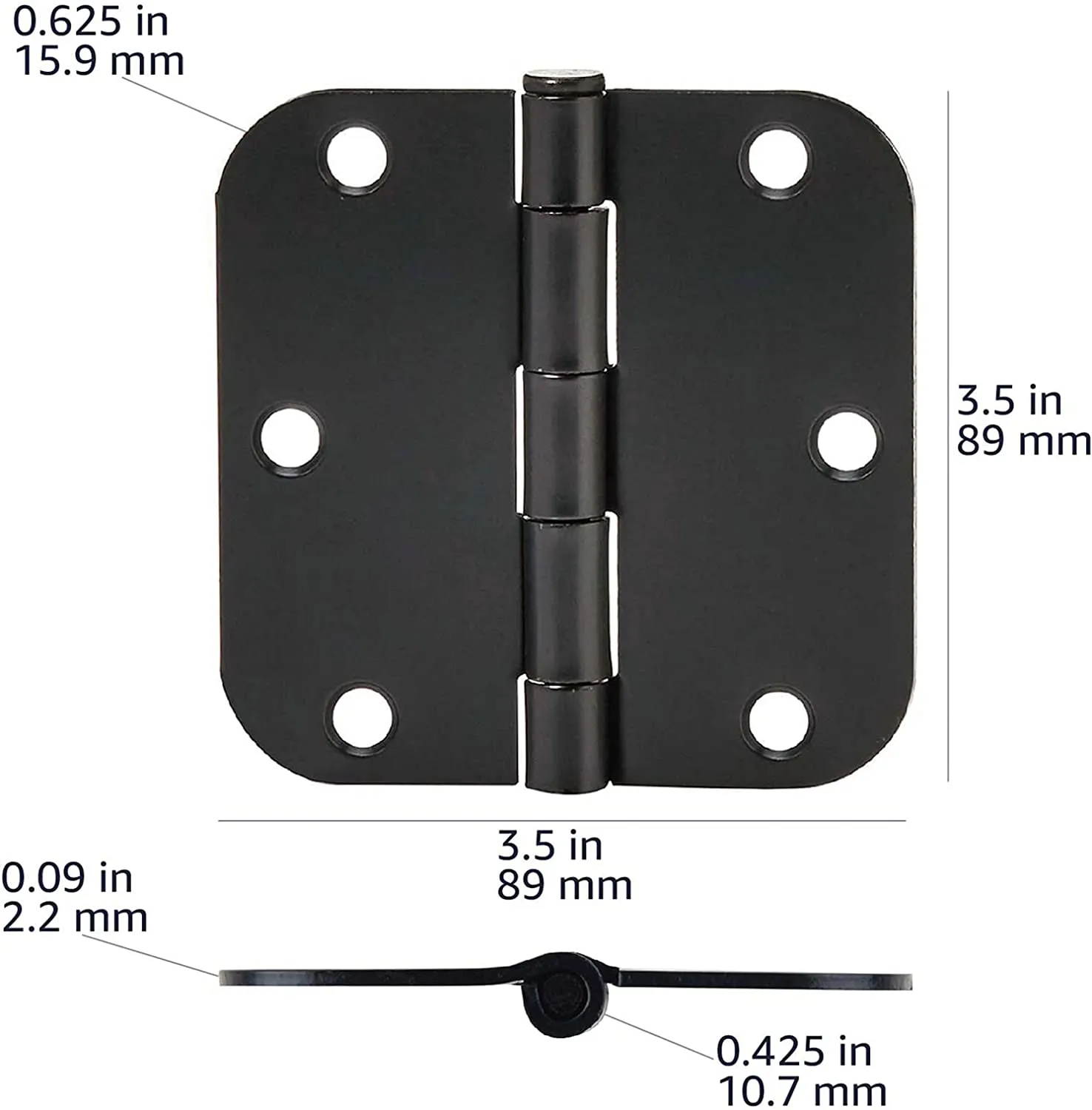

Measuring Hinge Size

Accurate hinge sizing ensures that doors operate smoothly and remain stable over time. Professionals measure the door’s width at the center and the height from top to bottom. They also check the thickness at the inner edge near the lock. The following table provides recommended hinge sizes based on door thickness and width:

Door Thickness | Door Width | Recommended Hinge Size |

|---|---|---|

1 ⅜” | Up to 32” | 3 ½” |

1 ⅜” | 32” to 36” | 4” |

1 ¾” | Up to 36” | 4 ½” |

1 ¾” | 36” to 48” | 5” |

1 ¾” | Over 48” | 6” |

To determine the radius of a hinge, measure from the top down to where the rounded area ends. Some installers use coins to gauge the radius corners for a precise fit.

Hinge Placement Rules

Proper hinge placement supports door weight and prevents sagging. Installers place the top hinge 5 to 7 inches from the top edge and the bottom hinge 10 to 11 inches from the bottom. If a third hinge is needed, it sits equidistant between the top and bottom hinges. For every 30 inches of door height, one hinge is recommended. This rule helps maintain stability and performance for both residential and commercial doors.

Number of Hinges Needed

The number of hinges on door depends on its height and weight. Doors up to 60 inches require two hinges. Doors between 60 and 90 inches need three hinges. For doors over 90 inches, four hinges or a continuous hinge is advisable. Heavy doors may require more than four hinges to ensure proper support and longevity.

Hinge Materials and Finishes

Material Choices

Selecting the right material for hinges on door depends on the environment and expected wear. Stainless steel offers high strength and resists corrosion, making it ideal for damp or coastal areas. For environments with high humidity, 304 stainless steel maintains both appearance and durability longer than zinc-coated or brass options. In coastal or industrial settings, 316 stainless steel provides extra protection against salt and chemicals. The table below compares common materials and their best uses:

Material | Key Benefits | Suitable Environments |

|---|---|---|

Stainless Steel | High strength, corrosion resistance | Damp or coastal environments |

304 Stainless Steel | Maintains strength and appearance in humidity | Humid conditions |

316 Stainless Steel | Extra protection in salty or chemical-rich settings | Coastal and industrial settings |

Hinge Finishes

The finish on a hinge affects both style and performance. Homeowners and builders should match finishes to the room’s decor while considering long-term durability. For example, satin nickel or PVD black finishes work well in coastal or high-humidity areas, using PVD coating for extra protection. Matte black or polished chrome suits modern interiors, while antique brass fits vintage or rustic homes. The following table shows how to select finishes for different scenarios:

Application Scenario | Recommended Finish | Suggested Coating Technology |

|---|---|---|

Coastal / High Humidity | Satin Nickel / PVD Black | PVD |

Modern Interior Doors | Matte Black / Chrome | Powder Coating / Electroplating |

Vintage / Rustic Homes | Antique Brass | Electroplating |

Commercial / High Traffic | Matte Black / Satin Nickel | Powder Coating |

Outdoor Gates / Garden Doors | PVD-Coated Black or Brass | PVD |

Tip: Always check that screws and fasteners match the hinge finish for a cohesive look.

Durability and Maintenance

Different surface finishes impact how often hinges need care and how well they resist corrosion. The table below outlines the maintenance needs for common finishes:

Surface Finish Type | Corrosion Resistance | Maintenance Requirements |

|---|---|---|

Standard Finish | Low | High |

Stainless Steel | High | Low |

Powder Coated | Moderate | Moderate |

Stainless steel hinges require less maintenance and last longer, especially outdoors. Powder-coated finishes offer moderate protection and suit high-traffic areas. Standard finishes need frequent cleaning and may not last as long in harsh conditions.

Common Mistakes to Avoid

Wrong Hinge Size or Type

Selecting the wrong hinge size or type often leads to operational problems and higher maintenance costs. Many installers overlook the importance of matching hinge strength to door weight and usage. The table below highlights frequent installation errors, their risks, and the resulting maintenance costs:

Installation Error | Risk | Maintenance Cost Implication |

|---|---|---|

Misaligned hinges | Door binding, uneven wear | Increased repair frequency |

Incorrect screw selection | Loosening, detachment | Frequent re-tightening or replacement |

Skipped pre-drilling | Weak anchoring | Door sagging, hinge damage |

Choosing the correct hinge and hardware prevents these issues and extends the life of the door.

Poor Measurement

Accurate measurement ensures proper door alignment and smooth operation. When installers fail to line up hinges correctly, doors may not swing as intended. This misalignment increases friction and accelerates wear on both the door and the frame. In one commercial office building, repeated door jamming and frame damage resulted from misaligned hinges. Technicians restored smooth operation by correcting the alignment with a laser level. Precise measurement at every step helps avoid costly repairs and ensures reliable performance.

Ignoring Weatherproofing

Neglecting weatherproofing exposes exterior door hinges to several risks:

Rusting or seizing can occur, compromising door security.

Environmental exposure may cause hinges to deteriorate over time.

Marine-grade stainless steel or powder-coated finishes offer better protection.

Annual lubrication with silicone-based grease helps maintain hinge function.

Tip: Always select weather-resistant materials for exterior doors to ensure long-term durability and security.

Tips for the Right Choice

Match Style to Room

Hinges do more than support doors. They also contribute to the overall look of a space. Homeowners often select finishes that match door handles, locks, or light fixtures. For example, matte black hinges create a modern feel in kitchens or bathrooms. Antique brass works well in traditional or rustic rooms. Designers recommend choosing concealed hinges for minimalist interiors. These hinges keep lines clean and uncluttered. Visible hinges with decorative tips can add character to vintage or industrial spaces.

Tip: Consistency in hardware finish helps unify the style of a room.

Balance Budget and Quality

Buyers should consider both cost and durability when selecting hinges. Stainless steel hinges cost more but last longer, especially in humid or coastal areas. Powder-coated options offer a balance between price and protection. Homeowners can save money by using standard finishes on interior doors that see less use. For exterior or high-traffic doors, investing in higher-quality hinges prevents frequent replacements and repairs.

Hinge Type | Cost Level | Best Use Case |

|---|---|---|

Standard Finish | Low | Interior, low-traffic |

Powder Coated | Medium | Interior/exterior |

Stainless Steel | High | Exterior, high-traffic |

When to Get Expert Help

Some situations require advice from a door hardware expert. These include:

High-traffic commercial doors need hinges made from materials with high fatigue resistance.

Doors with unusual weight or frequent use require careful hinge selection.

Doors that need self-closing or advanced security features benefit from professional guidance.

Proper installation prevents problems like sagging or squeaking.

Note: An expert ensures the right hinge choice and installation for long-lasting performance.

Industry professionals recommend several key steps for selecting door hinges:

Choose the correct hinge type for the application.

Coordinate finish and aesthetics.

Verify certifications and standards.

Consider environmental and usage factors.

Select reputable suppliers.

Careful measurement and expert advice ensure optimal function, security, and style. 🛠️

FAQ

What is the most common hinge for residential doors?

Butt hinges appear most often in homes. They provide reliable support and allow doors to swing smoothly in everyday use.

How often should someone lubricate door hinges?

Experts recommend lubricating door hinges every six months. Regular maintenance prevents squeaking and extends hinge life.

Can exterior door hinges rust?

Yes, exterior door hinges can rust. Stainless steel or powder-coated finishes resist corrosion and last longer in outdoor environments.

Related articles

-

A Complete Guide to Hinge Types for Modern Projects

Hinge types offer unique benefits for doors, cabinets, and gates. Compare features, materials, and uses to select the best hinge for your modern project.Jan-16-2026 Learn More >> -

Exploring the Benefits of Double Spring Hinges for Commercial Spaces

Double spring hinge boosts commercial space safety, accessibility, and energy efficiency with automatic bidirectional door closing.Jan-16-2026 Learn More >> -

Choosing the Right Support for Your Gate Hinges

Find the best support on which gate hinges for your gate by matching hinge type, material, and installation to gate size and weight for lasting durability.Jan-16-2026 Learn More >>

To Provide You with Better Service

Contact

Tel: +8613325838282

Add: 6265 Providence Way Eastvale,CA 92880