How Industrial Hinges Are Shaping Manufacturing Trends in 2026

How Industrial Hinges Are Shaping Manufacturing Trends in 2026

Industrial hinges serve as critical components in manufacturing. These devices drive innovation by supporting advanced machinery and flexible product designs. Recent market research highlights robust growth:

The industrial hinges market reached $1.5 billion in 2023.

Projections estimate $2.1 billion by 2032, with a 5.0% CAGR.

Key Functions of Industrial Hinges

Modular Design Enablement

Industrial hinges play a vital role in modular manufacturing environments. Manufacturers rely on these components to create systems that can be quickly assembled, disassembled, or reconfigured. Heavy-duty hinges and butt hinges are often chosen for their strength and reliability in supporting large panels and doors. T-slot hinges allow for flexible attachment points, making them ideal for modular workstations and enclosures.

Tip: Modular designs benefit from hinges made of stainless steel. This material resists corrosion and maintains structural integrity, even in harsh industrial settings.

A modular approach increases efficiency and reduces downtime. Engineers can swap out sections of machinery or adjust layouts without extensive rework. This adaptability supports rapid prototyping and customization, which are essential in industries such as automotive and consumer electronics.

Automation and Robotics Support

Automation and robotics have transformed manufacturing. Industrial hinges enable precise movement and positioning in automated systems. Several hinge types are commonly used in robotic arms and assembly lines:

Revolute joints provide rotation around a single axis, essential for tasks like welding and assembly.

Prismatic joints enable linear movement, allowing robotic sliders and extendable arms to achieve accurate positioning.

Spherical joints offer multi-directional movement, which is critical for robotic wrists handling complex objects.

Universal joints facilitate rotation around two axes, supporting smooth operation in robotic manipulators.

Cylindrical joints combine rotational and linear motion, useful for applications that require both types of movement.

Friction hinges and 360-degree torque hinges are also used in automation. These hinges allow controlled movement and hold positions securely, which is important for safety and repeatability. Stainless steel hinges are preferred in automated environments due to their durability and resistance to wear.

Durability and Safety Enhancement

Manufacturers demand hinges that withstand heavy use and harsh conditions. Industrial hinges made from stainless steel offer superior durability and corrosion resistance. Heavy-duty hinges support large doors and panels, ensuring safe operation in factories and warehouses. Butt hinges provide reliable pivot points for machinery access panels.

A focus on safety drives the adoption of hinges with enhanced load-bearing capacity and fail-safe features. Friction hinges prevent accidental movement, reducing the risk of injury. 360-degree torque hinges maintain stable positions, which is crucial for equipment that must remain open or closed during operation.

Hinge Type | Key Feature | Typical Application |

|---|---|---|

Heavy-duty | High load capacity | Factory doors, machinery |

Butt | Simple pivot | Access panels, enclosures |

T-slot | Modular attachment | Workstations, frames |

Friction | Controlled movement | Safety covers, robotics |

360-degree torque | Position holding | Automated equipment |

Industrial hinges contribute to safer workplaces by supporting reliable access and movement. Their robust construction and material selection help manufacturers meet strict safety standards.

Types of Industrial Hinges

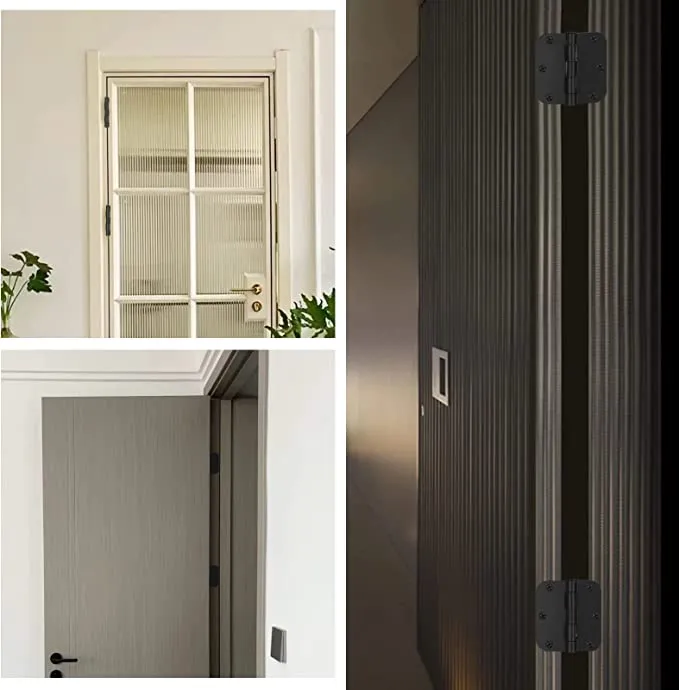

Heavy-Duty and Butt Hinges

Heavy-duty hinges and butt hinges are essential in many manufacturing environments. Heavy-duty hinges support large doors, machinery covers, and panels that experience frequent movement or high forces. Butt hinges, with their simple design and fixed pin connection, are common on access panels and cabinet doors.

Feature | Heavy-Duty Hinges | Butt Hinges |

|---|---|---|

Load-Bearing Capacity | 20-200 kilograms | Standard load capacity |

Corrosion Resistance | Strong, withstands rain and salt spray | Varies, generally less resistant |

Service Life | Long-lasting, wear-resistant design | Standard durability |

Construction | Engineered for heavy use | Simple design, fixed pin connection |

Manufacturers choose heavy-duty hinges for metal doors and equipment in areas with extreme forces. These hinges are ideal for machinery that undergoes frequent use. TDC Stainless steel is a preferred material because it resists corrosion and extends service life.

T-Slot and Friction Hinges

T-slot hinges provide modular attachment points. They allow engineers to build flexible workstations, frames, and enclosures. These hinges make it easy to reconfigure layouts or add new components without major changes.

Friction hinges control movement and hold positions securely. They are used on safety covers, robotics, and panels that must stay open or closed. Friction hinges help prevent accidental movement, which improves workplace safety.

Note: Stainless steel T-slot and friction hinges offer excellent durability in demanding environments.

360-Degree Torque Hinges

360-degree torque hinges allow continuous rotation and precise position control. These hinges are valuable in automated equipment and robotics. They hold panels or arms at any angle, which supports complex movements and adjustments.

Manufacturers use 360-degree torque hinges in applications that require both flexibility and stability. Stainless steel construction ensures these hinges perform well in harsh conditions.

2026 Trends in Industrial Hinges

Customization and Smart Features

Manufacturers now expect industrial hinges to deliver more than basic movement. Customization drives the market, with companies seeking hardware that fits unique design needs and space constraints. Smart hinges have become popular due to their advanced technology. Many models feature sensors and Bluetooth connectivity, allowing remote control through smartphone applications. Automatic safety functions prevent damage when doors or panels encounter obstacles. These innovations transform hinges into intelligent components that improve user interaction and workplace safety.

Smart hinges support predictive maintenance. Sensors monitor hinge performance and alert technicians before failures occur, reducing downtime.

Lightweight and Sustainable Materials

Sustainability shapes material selection for industrial hinges in 2026. Manufacturers prefer high-performance alloys and composites that reduce weight without sacrificing strength. Stainless steel remains a top choice for its durability and corrosion resistance, but new eco-friendly materials are gaining traction. Companies focus on reducing environmental impact by using recycled metals and biodegradable polymers. Lightweight hinges help lower energy consumption in automated systems and support easier installation.

Material | Benefit | Application Example |

|---|---|---|

Corrosion resistance | Factory doors, robotics | |

Composites | Lightweight strength | Modular panels, enclosures |

Recycled Metals | Sustainability | Green manufacturing |

IoT and Industry 4.0 Integration

Industrial hinges now play a role in connected manufacturing environments. Integration with IoT platforms enables real-time monitoring and data collection. Smart hinges communicate with central systems, providing updates on usage and wear. Artificial intelligence analyzes this data to optimize maintenance schedules and predict failures. These features support Industry 4.0 goals by improving efficiency and reducing costs. Growth in regions like Southeast Asia and Africa highlights the global demand for advanced hinge solutions as urbanization accelerates.

Applications and Case Studies

Automotive Manufacturing

Automotive factories rely on precise movement and secure access. Engineers use heavy-duty and friction hinges in assembly lines for doors, hoods, and robotic arms. These hinges allow quick panel removal and easy maintenance. In electric vehicle production, lightweight hinges help reduce overall car weight. This supports better energy efficiency and faster assembly times.

Note: Automotive manufacturers often select hinges with corrosion-resistant coatings to withstand exposure to chemicals and moisture.

Aerospace and Defense

Aerospace and defense sectors demand high-performance hardware. Aircraft doors, control panels, and access hatches use specialized hinges that must handle extreme stress and vibration. Stainless steel and composite hinges provide strength without adding unnecessary weight. Defense vehicles use reinforced hinges for armored panels and equipment bays. Engineers test these components under harsh conditions to ensure safety and reliability.

Application Area | Hinge Type Used | Key Requirement |

|---|---|---|

Aircraft doors | Heavy-duty, friction | High strength, safety |

Control panels | T-slot, butt | Precision, durability |

Armored vehicles | Reinforced, torque | Impact resistance |

Consumer Electronics

Consumer electronics require compact and reliable movement. Designers use friction and 360-degree torque hinges in laptops, tablets, and smart appliances. These hinges allow screens and panels to hold any position. Modular designs make repairs and upgrades easier. The use of industrial hinges in electronics ensures smooth operation and long product life.

Tip: Choosing the right hinge improves user experience and reduces warranty claims.

Challenges and Future Opportunities

Supply Chain and Standardization

Manufacturers face ongoing challenges in sourcing industrial hinges. Global supply chains remain vulnerable to disruptions from geopolitical tensions, natural disasters, and material shortages. These risks can delay production and increase costs. Companies must secure reliable suppliers and diversify their sourcing strategies.

Standardization presents another challenge. Many industries require hinges with unique specifications. This diversity complicates inventory management and quality control. Lack of universal standards can slow down assembly and maintenance. Industry groups are working to develop common guidelines for hinge dimensions, materials, and performance. Standardized hinges will help manufacturers streamline procurement and reduce downtime.

Tip: Partnering with certified suppliers ensures consistent quality and compliance with international standards.

Innovations Beyond 2026

The future of industrial hinges looks promising. Smart hinges with embedded sensors will become more common. These devices will monitor movement, detect wear, and send real-time data to maintenance teams. Artificial intelligence will analyze this information to predict failures before they occur.

Sustainable materials will gain importance. Manufacturers will adopt recycled metals and bio-based polymers to reduce environmental impact. Lightweight composites will support energy-efficient machinery and robotics.

Emerging technologies like additive manufacturing will enable custom hinge designs. Engineers will create parts with complex geometries that traditional methods cannot produce. This flexibility will drive innovation in product design and manufacturing processes.

The next generation of industrial hinges will combine durability, intelligence, and sustainability to meet the demands of advanced manufacturing.

Industrial hinges drive progress in manufacturing by improving innovation, efficiency, and adaptability. These components support new product designs and advanced automation. Manufacturers will continue to rely on industrial hinges as technology evolves. The future promises smarter, more sustainable solutions for every industry.

FAQ

How are stainless steel hinges used in industrial applications?

Stainless steel hinges provide corrosion resistance and durability. Manufacturers use them in machinery, enclosures, and access panels where strength and longevity are critical.

How to adjust Nationwide Industries stainless steel self-closing hinges?

Use a screwdriver to turn the tension adjustment pin. Increase or decrease tension until the hinge closes the gate or door at the desired speed.

How to replace a pivot hinge in an industrial glass door?

Remove the door from the frame. Unscrew the old pivot hinge. Install the new hinge, then rehang the door and check alignment.

Related articles

-

Everything You Need to Know About Residential Door Hinges

Find the best residential door hinges for your home by matching hinge type, size, and material to your door’s weight, location, and usage needs.Jan-26-2026 Learn More >> -

How to Choose the Right Door Hinge Size

Choose the right door hinge sizes by matching hinge height to your door’s thickness, height, and weight for smooth operation and lasting support.Jan-26-2026 Learn More >> -

Choosing the Right Outdoor Hinges for Your Garden Gates

Select outdoor hinges by matching hinge type, size, and material to your garden gate’s weight, width, and weather for lasting performance.Jan-26-2026 Learn More >>

To Provide You with Better Service

Contact

Tel: +8613325838282

Add: 6265 Providence Way Eastvale,CA 92880