Adjusting Self-Closing Hinge Tension

Self-closing hinges come in various forms (spring-loaded, adjustable-tension, hydraulic, etc.) and are used on residential and commercial doors as well as cabinets to ensure doors close automatically.

The following table provides a functional overview of common self-closing hinge typologies:

Hinge Type | Core Mechanism | Typical Applications | Primary Adjustment Points | Advantages | Limitations |

Spring-Loaded | Tightly wound spring | Residential doors, light commercial | Tension pin/screw | Cost-effective, simple installation | Less precise speed control, limited load capacity |

Hydraulic | Fluid damper | High-traffic commercial, fire doors | Speed ('S') and Latching ('L') valves | Smooth, controlled closure, adjustable speed | Higher complexity, potential for fluid leaks |

Cam-Action | Contoured cam with follower | Modern architectural designs, specialized doors | Cam profile, associated spring tension | Unique aesthetic, specific pivot points | Less common for general tension adjustment, specialized installation |

Preparation & Tools

Before adjusting, gather basic tools: a flathead or Phillips screwdriver (for hinge screws), a hex (Allen) wrench, and any provided tension pins or rods. Most spring hinges include a hex hole on top for tuning, and sometimes a removable tension pin. In all cases, ensure the door is closed and locked (if applicable) to avoid injury. It’s also wise to have a level or shim (book/cardboard) ready to hold the door slightly open if needed while working.

General principle: turning the tension screw clockwise increases closing force, counterclockwise decreases it.

If you reach a clicking position with a hex wrench, lock in place and reinsert any tension pin. Always adjust gradually and test often—too much tension can slam the door, too little will leave it ajar.

TDC’s self-closing door hinges often feature an adjustment screw at the top or end of the arm. Turning this screw clockwise raises tension; turning it back relieves tension.

Residential Door Hinges: Step-by-Step Adjustment

For standard home or light-office doors, TDC’s 3.5″ or 4″ self-closing spring hinges are typical. These usually have an exposed hex socket (Allen) or a cover screw on top. Here’s how to adjust them:

● Inspect and prepare: Make sure hinge pins and springs are in good condition. Lubricate if stiff. If the hinge has a small locking screw on top, remove it first with a screwdriver. (Not all models have this.)

● Insert the adjustment tool: Use the provided hex wrench (usually supplied by TDC) into the hole at the top of the hinge barrel. Wiggle it until it seats into the hex recess. Position the long end of the wrench at a 45° angle for leverage, as recommended.

● Set the tension:

○ If the door isn’t closing fully, rotate the wrench clockwise one click at a time. Each “click” re-positions the internal cam, increasing spring force.

○ If the door slams, rotate counterclockwise to back off tension.

○ Make adjustments slowly and test the door after each click. It should “creep” closed at a steady pace, latching without banging.

● Lock it in place: Once satisfied, reinsert the tension pin/screw (if removed) into the newly selected hole. This secures the spring setting. Then replace any cover screw and tighten flush.

● Balance double hinges: If your door has two self-closing hinges (TDC recommends top and bottom for heavy doors), repeat the adjustment on the second hinge so both are equally tensioned. Uneven tension can cause binding.

● Test thoroughly: Open and close the door several times to ensure smooth, quiet closing. The door should close from any angle to just before latching (so it catches easily), without excessive speed. If needed, fine-tune by backing off a bit or cranking a bit more.

Commercial/Heavy-Duty Doors: Procedures & Considerations

Commercial settings use larger doors (6–7 ft) and often heavy-duty hinges. TDC’s commercial lineup includes 5″ or 6″ self-closing spring hinges, heavy-gauge steel models, and even unit hinges. The adjustment procedure is similar in principle but note:

● Multiple springs: Some heavy hinges contain more than one spring. TDC’s heavy-duty hinges often require a tension rod (rather than Allen key) to adjust. If you see a side slot with holes, use the tension rod (provided with the hinge) to engage the spring cam. Rotate the rod as needed to adjust tension, then insert the locking pin back.

● Hold-open or larger cams: Many commercial springs include a hold-open feature. To adjust these, you may need to crank past the hold-open notch. Always follow the hinge’s instructions. In general, clockwise still tightens and CCW loosens.

● Code requirements: Commercial doors often must self-close for fire and security codes. Ensure hinge size matches door weight (e.g. 2 ½–3/16″ thick, 8–12 screws) as required by law.

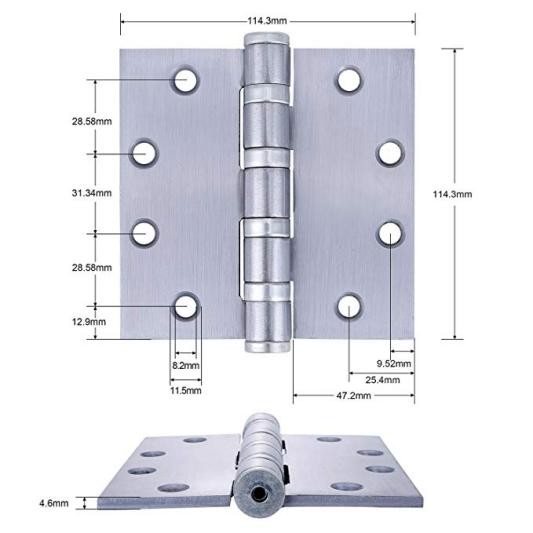

● Example: A common TDC product is the 4.5″ Stainless Steel Self-Closing Spring Hinge. It comes with set screws and is designed for high-traffic use. Adjust it like any spring hinge: remove cover screw, use hex wrench to set, then re-secure. Its stainless steel construction provides corrosion resistance for durable performance.

TDC’s steel self-closing hinge uses a concealed spring to pull the door shut. The high-grade steel construction is “highly rust resistant,” and the hinge comes with matching screws for easy installation.

The following table provides a quick reference for troubleshooting common self-closing hinge problems:

Common Problem | Probable Cause(s) | Immediate Solution(s) | When to Call a Professional |

Door Slams Shut | Excessive tension, aggressive speed setting | Decrease tension (counter-clockwise) | Persistent issues after multiple adjustments |

Door Doesn't Close Fully | Insufficient tension, obstruction, misalignment | Increase tension (clockwise), remove obstruction, realign hinge | Persistent issues, structural damage to door/frame |

Squeaking/Grinding Noises | Dirt/debris accumulation, lack of lubrication | Clean thoroughly, lubricate with silicone-based product | Noise persists after cleaning & lubrication, visible damage |

Loose Door/Hinge | Loose mounting screws, worn components | Tighten screws, replace stripped screws (with wood filler if needed) | Severe damage/wear, hinge is leaking fluid (hydraulic) |

Adjusting a self-closing hinge’s tension is usually as simple as turning a set screw or using a tension pin—tighten to speed up closing, loosen to slow it down.

TDC Hinges’ products are exemplary in this regard. Our self-closing hinges are engineered for durability and serviceability, from premium stainless steel springs to included adjustment tools. By using the correct procedure and quality hinges, facility managers and construction professionals can ensure doors close quietly, safely, and reliably every time.

If you need further consultation and discussion, please feel free to contact us.

Email: kathy@tdc-hardware.com

WhatsApp / Cell: +8613325838282

To Provide You with Better Service

Contact

Tel: +8613325838282

Add: 12819 Telegraph Road Santa Fe Springs, CA 90670