Comprehensive Guide on Types of Exterior Door Hinges

You may encounter several types of exterior door hinges, such as butt, ball bearing, and concealed options. Hinge selection depends on door thickness, height, and security requirements. The table below outlines typical hinge sizes and recommendations for an exterior door:

Door Thickness Range | Typical Hinge Size | Door Height Range | Number of Hinges Recommended |

1-3/8" | 3-1/2" x 3-1/2" | Up to 60" | 2 Hinges |

1-3/4" | 4" x 4" | 60" to 80" | 3 Hinges |

2" | 4-1/2" x 4-1/2" | 80" to 97" | 4 Hinges |

2-1/4" to 2-3/4" | 5" x 5" | 97" to 109" | 5 Hinges |

Over 2-3/4" | 6" x 6" | Over 109" | 6 Hinges |

· Choose commercial door hinges based on door size, weight, and security needs to ensure proper support and durability.

· Select hinge materials like stainless steel for weather resistance and long-lasting performance, especially in harsh or coastal environments.

· Maintain hinges by cleaning and lubricating them annually to keep doors operating smoothly and extend hinge life.

Different Types of Exterior Door Hinges

Butt Hinges

Butt hinges remain the most common choice for security door hinges in residential and commercial settings. These hinges consist of two rectangular leaves joined by a central pin, allowing the door to pivot smoothly. TDC produce butt hinges in various materials, including steel, brass, and stainless steel, to suit different environments and security needs. Many models offer ball bearing or oil-impregnated knuckles for enhanced performance.

Tip: Butt hinges with ball bearings reduce friction and extend hinge life, making them ideal for heavy exterior doors.

A typical stainless steel butt hinge, such as the RH353522-5/8R-US19(US1D), measures 3.5" x 3.5" and supports doors weighing up to 264 lbs. These hinges comply with industry standards like EN 1935:2002, ensuring durability and reliability. While butt hinges offer a low initial cost and a wide range of configurations, they may require more maintenance over time compared to other types.

Hinge Size (hgt. x wdth.) | Number | Gauge of | Pin | |||||

Inches | Millimeters | Holes | Metal | Diameter | ||||

3.5" x 3.5" | 88.9 x 88.9 | 6 | 0.087" | 0.232" | ||||

Screw Size | Quantity | Avg. Weight | ||||||

Machine | Wood | Inner Box | Case | Per Case (lbs.) | ||||

None | #9 x 3/4" | Bulk | 100 Pcs. | 40 | ||||

Ball Bearing Hinges

Ball bearing hinges represent an upgrade over standard butt hinges, especially for exterior hinges exposed to frequent use or heavy loads. These hinges incorporate ball bearings between the knuckles, which significantly reduce friction and wear. Manufacturers such as TDC design ball bearing hinges to support doors weighing from several hundred to over 2,000 lbs, depending on the model.

Ball bearing hinges often feature non-removable pins for added security, making them suitable for high-traffic entryways and security doors. High-strength carbon or stainless steel construction, along with corrosion-resistant coatings, ensures long-lasting performance in outdoor environments. Many products come with lifetime mechanical warranties, reflecting their reliability and durability.

Continuous (Piano) Hinges

Continuous hinges, also known as piano hinges, run the full length of the door and frame. This design distributes the door’s weight evenly, reducing stress on the frame and hinge points. Piano hinges are available in steel or anodized aluminum, with corrosion-resistant finishes for exterior applications.

Hinges.jpg)

Laboratory testing shows that geared continuous hinges can withstand over 25 million open and close cycles, equating to approximately 60 years of high-traffic use. These hinges require virtually no maintenance and provide excellent durability, making them a preferred choice for commercial buildings and public facilities. Fire-rated and ballistic-resistant options are also available for enhanced safety.

Pivot Hinges

Pivot hinges support the door at the top and bottom rather than the side, allowing for smooth rotation and reduced sagging. These hinges excel in supporting heavy or oversized doors, with some models capable of handling loads up to 800 lbs using just two hinges. TDC design pivot hinges with multi-pivot geometry, enabling doors to lift out of the frame and maintain perfect alignment over time.

Pivot hinges often feature corrosion and UV resistance, making them suitable for various materials, including glass, stone, timber, and metal. However, they may require more maintenance in outdoor environments due to potential corrosion issues. Their unique installation allows for seamless paneling and minimal gaps, enhancing both function and appearance.

Strap Hinges

Strap hinges combine decorative appeal with structural support. Their long, slender leaves provide extra stability, making them popular for gates, barn doors, and rustic or vintage-style entryways. TDC offer strap hinges in materials such as steel, aluminum, brass, and copper, each providing different levels of durability and corrosion resistance.

Strap hinges not only secure the door but also add a distinctive design element. Their visible placement and range of finishes allow homeowners to match the hinge style to the overall aesthetic of the property. While strap hinges offer excellent grip and support, they may come at a higher price point compared to standard butt hinges.

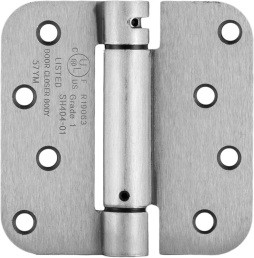

Spring Hinges

Spring hinges incorporate a built-in spring mechanism that automatically closes the door after opening. These hinges are commonly used for exterior doors that require self-closing functionality, such as garage entry doors or fire-rated doors. Spring hinges help maintain security and energy efficiency by ensuring the door remains closed when not in use.

TDC produce spring hinges in various sizes and finishes to accommodate different door weights and styles. Adjustable tension settings allow for customization of the closing force, providing flexibility for residential and commercial applications.

Concealed Hinges

Concealed hinges, sometimes called invisible or European hinges, remain hidden when the door is closed. This design enhances security by eliminating external access points, making it difficult for intruders to tamper with the hinges. Concealed hinges consist of two interconnecting plates installed within mortises in the door and frame, allowing for smooth, hidden operation.

Manufacturers use durable materials such as stainless steel, aluminum, brass, and zinc alloys to ensure longevity and corrosion resistance. Concealed hinges often feature adjustable settings for precise alignment and may include soft-closing mechanisms for added convenience. Their sleek, uninterrupted appearance makes them a popular choice for modern homes seeking both security and style.

How to Choose Exterior Door Hinges

Material and Finish

Material selection plays a crucial role in the performance and longevity of tamper proof door hinges. Stainless steel hinges, for example, offer high durability and corrosion resistance, making them suitable for outdoor environments. A stainless steel hinge with a plain finish can support significant loads, with some models rated for up to 36.8 ft-lbs.

Know More About TDC Anodizing

Anodizing is a conversion coating process used to achieve an oxidized surface finish on furniture hardware. It increases the thickness of the naturally occurring oxide layers on metal, enhancing the finished part’s corrosion and wear resistance. Compared to other finishing methods, the process results in a durable, long-lasting protective layer that is part of the metal rather than sitting atop its surface.

Security Features

Security remains a top priority. Rising public concern about home safety drives demand for dependable and long-lasting hinges. Features such as non-removable pins, concealed mounting, and self-closing mechanisms enhance protection. Heavy Duty Butt hinges are often preferred for their ability to support heavy doors and integrate security components. Concealed hinges further reduce tampering risks by hiding the hinge mechanism from view.

Weather Resistance

External door hinges must withstand harsh weather conditions. Stainless steel and anodized aluminum resist rust and corrosion, ensuring reliable operation over time. Proper material selection prevents premature wear, especially in coastal or humid environments.

Ease of Installation

Proper installation directly impacts hinge functionality and lifespan.

1. Align hinges precisely on the door and frame for smooth movement.

2. Use a hinge boring jig to drill accurate screw holes.

3. Secure screws after alignment checks to prevent misalignment.

4. Maintain hinges by cleaning and lubricating annually.

5. Inspect regularly for wear or damage to extend service life.

A careful approach to installation ensures outdoor hinges operate smoothly and last for years.

FAQs

What is the best hinge material for coastal houses?

Stainless steel resists corrosion from salt air. Houses in coastal areas often choose stainless steel hinges for long-lasting performance and minimal maintenance.

How often should outside door hinges be maintained?

Annual cleaning and lubrication keep hinges operating smoothly. Regular inspection helps identify wear or damage before it affects door function.

Can I install exterior door hinges myself?

Most people can install hinges with basic tools. Precise alignment and secure fastening ensure proper operation and extend hinge lifespan.

If you need further consultation and discussion, please feel free to contact us.

Email: kathy@tdc-hardware.com

WhatsApp / Cell: +8613325838282

To Provide You with Better Service

Contact

Tel: +8613325838282

Add: 6265 Providence Way Eastvale,CA 92880