Heavy Duty T Hinge Guide For Easy Gate Upgrades

You want your gate to stay strong and secure for years. A heavy duty t hinge gives you a simple way to upgrade your gate without hiring a professional. You can install these hinges yourself and see instant results. Quality hardware with the right finish keeps your gate looking good and working well. Choose the best materials and enjoy peace of mind knowing your gate stands up to daily use.

● Heavy duty T hinges provide strong, durable support that prevents gate sagging and lasts through heavy use.

● Choose the right hinge size and material based on your gate’s weight, size, and local weather conditions for best results.

● Proper installation with pilot holes, level alignment, and diagonal bracing ensures smooth gate operation and long hinge life.

● Regular cleaning, lubrication, and inspection keep your hinges working smoothly and prevent rust or damage.

● Quality finishes like galvanization and stainless steel protect hinges from weather, extending their lifespan and appearance.

What Is a Heavy Duty T Hinge

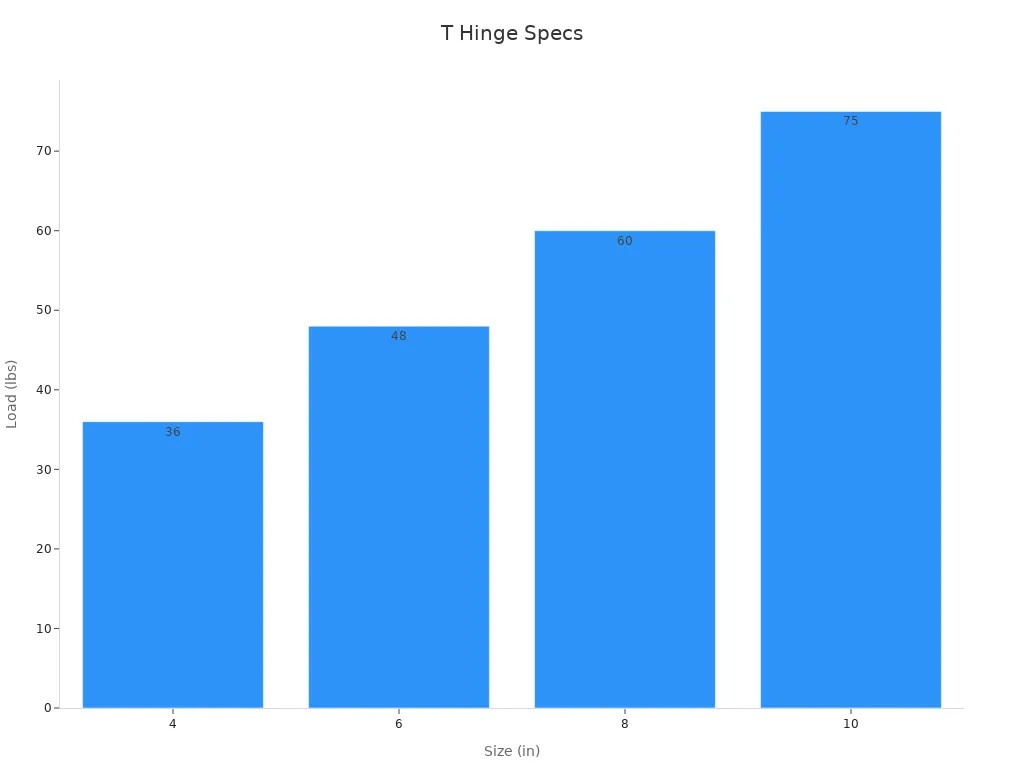

A T hinge gets its name from its shape. The long strap forms the top of the “T,” while the shorter part attaches to the gate post or frame. You use a T hinge to connect a swinging gate or door to a fixed post. The design spreads the weight of the gate across a larger area, which helps prevent sagging. Heavy duty t hinge models use thicker steel and advanced finishes to handle more weight and resist weather damage. For example, you can find sizes like 4, 6, 8, and 10 inches, each with a specific safe working load. An 8-inch hinge can support up to 60 pounds, while a 10-inch hinge can hold up to 75 pounds.

Size (inches) | Safe Working Load (lbs) | Material & Finish | Additional Features |

4 | 36 | Hot-rolled steel, Stainless Steel, WeatherGuard coating | Offset screw holes, tight pin, heavy-duty, 2 pack |

6 | 48 | Hot-rolled steel, Stainless Steel, WeatherGuard coating | Offset screw holes, tight pin, heavy-duty, 2 pack |

8 | 60 | Hot-rolled steel, Stainless Steel, WeatherGuard coating | Offset screw holes, tight pin, heavy-duty, 2 pack |

10 | 75 | Hot-rolled steel, Stainless Steel, WeatherGuard coating | Offset screw holes, tight pin, heavy-duty, 2 pack |

Key Features

You will notice several features that set a heavy duty t hinge apart from standard hinges. These hinges use thicker metals, such as solid brass or stainless steel, for extra strength. They often include premium ball or roller bearings, which allow the gate to swing smoothly and quietly. Heavy duty t hinges also pass strict cycle tests, with some rated for over 1,000,000 open and close cycles. Reinforced mounting points and enhanced corrosion resistance make them ideal for outdoor use. The advanced finishes, like galvanization or WeatherGuard coatings, protect against rust and wear.

Tip: Choose a heavy duty t hinge with offset screw holes for better grip and stability on your gate.

Common Uses

You can use a heavy duty t hinge for many types of gates and doors. These include garden gates, shed doors, driveway gates, and even stable doors. The strong design supports wide or heavy gates, making it a top choice for high-traffic areas. You will also find these hinges on privacy fences and storage enclosures. Their durability and smooth operation make them suitable for both residential and commercial settings.

Benefits of Heavy Duty T Hinges

Strength and Durability

When you choose a heavy duty t hinge for gate, you give your gate the support it needs to last. These hinges use strong materials like stainless steel, solid brass, or carbon steel. Thicker plates and reinforced pins help them handle heavy loads without bending or breaking. Many models include protective coatings such as zinc plating or powder coating, which shield the metal from rust and weather damage. You can see the difference in their performance:

● High load-bearing capacity prevents sagging and warping.

● Weld-on and continuous hinges can support weights over 1,000 pounds.

● Industrial fatigue testing ensures thousands of open-close cycles without failure.

Factor | Details/Values |

Material Strength | Stainless Steel: 500–900 MPa |

Load Capacity | Weld-on: >1,000 lbs; Continuous: >600 lbs |

Plate Thickness | Thicker leaves distribute weight and reduce stress |

Pin Diameter | Larger pins improve load support |

Security and Longevity

You want your gate to stay secure year after year. Heavy duty t hinges help you achieve this goal. Their corrosion-resistant materials and advanced finishes protect against harsh weather and daily wear. Quality manufacturing and strict quality control reduce early wear and defects. You also benefit from easy maintenance, since these hinges allow for simple lubrication and inspection. Here are some reasons why they last longer:

● Even weight distribution prevents deformation and hinge failure.

● Protective coatings guard against corrosion, preserving hinge integrity.

● Suitable for harsh environments, they maintain function despite temperature swings.

Tip: Proper installation is key to maximizing the lifespan of your hinges and avoiding premature wear.

Smooth Operation

A gate should open and close smoothly every time. Heavy duty t hinges deliver reliable performance, even with frequent use. Many models use internal bearings or double knuckles to distribute weight and reduce friction. This design minimizes side play and end play, so your gate stays aligned and easy to move. You also get features like precise end plate tolerance and correct gauge thickness, which support smooth rotation without binding. Some hinges even offer adjustable friction for a custom feel. With these features, you enjoy:

● Minimal slop for a tight fit and smooth swing.

● Consistent movement, even after thousands of cycles.

● Reliable operation in all weather conditions.

Choosing Hinges

Size and Weight

Choosing the right hinge size and weight rating is the first step to a successful gate upgrade. You need to match the hinge to your gate’s height, width, and weight. If you use a hinge that is too small, your gate may sag or fail over time. If you pick one that is too large, you may spend more than necessary and face installation challenges.

The following table helps you compare hinge types and their recommended uses:

Hinge Type | Suitable Gate Size (ft) | Max Gate Weight (lbs) | Features/Notes |

Half Surface Gate Hinges | ~4 x 6 | Up to 150 | Self-closing, ADA compliant, hold-open option, suitable for half doors |

Butt Hinges | Up to 4 x 7 | Up to 120 | Mechanical/hydraulic closing, smooth and quiet operation, hold-open feature |

Full Surface Gate Hinges | Variable (metal posts) | Heavy duty | Corrosion resistant, suitable for coastal/outdoor, adaptable to 2", 3", 4" steel posts |

You should also consider the number of hinges needed. For gates under 60 inches tall or weighing less than 150 pounds, two hinges usually work well. For taller or heavier gates, use three or four hinges for better support. Larger and heavier gates require stronger hinges, such as weld-on or full surface models, to prevent sagging and ensure long-term performance.

Tip: Always check your gate’s measurements before buying hinges. A quick measurement can save you time and money.

Material and Finish

The material and finish of your hinge play a big role in how long it lasts and how well it performs. Stainless steel, hot-rolled steel, and heavy-duty alloys are popular choices for strength and resistance to cutting or grinding. For outdoor gates, you want a hinge that can handle rain, sun, and temperature changes.

Finishes like galvanization and anodizing add extra protection. Galvanized steel resists rust and corrosion, making it ideal for garden gates, shed doors, and other outdoor uses. Anodizing creates a thick, durable oxide layer on metal, which boosts corrosion and wear resistance. This means your heavy duty t hinge will last longer, even in tough environments.

● Stainless steel hinges work best for outdoor gates exposed to moisture.

● Galvanized or anodized finishes protect against rust and wear.

● Fire resistance and chemical resistance matter for high-security or industrial settings.

Environmental Factors

Your local environment affects how your hinges perform. If you live near the coast, salt in the air can speed up corrosion. In humid or rainy areas, moisture can cause rust. Gates in sunny spots face UV rays that may weaken some materials over time.

You should choose hinges with corrosion-resistant finishes if your gate faces harsh weather. For gates in dry, mild climates, standard steel or brass may work well. In high-traffic or commercial areas, pick hinges rated for frequent use and heavy loads.

● Outdoor hinges must resist UV rays, salt, rain, and temperature swings.

● Polymer spring hinges and commercial-grade spring hinges offer self-closing features and adjustability.

● Strap hinges and T-hinges provide extra stability for wide or heavy gates.

TDC Hinges Overview

TDC (Tendency Hardware) stands out as a leading manufacturer of door and home hardware. Since 1987, TDC has delivered high-quality hinges to customers worldwide. Located in Pinghu, China’s largest hinge distribution center, TDC benefits from excellent logistics and a strong supply chain. You can find TDC products in homes, businesses, and industrial sites across North America, Europe, the Middle East, Africa, and Southeast Asia.

TDC offers a wide range of heavy duty t hinge options, including models with galvanized steel construction and advanced finishes. Their hinges are designed for easy installation and minimal maintenance. TDC’s commitment to quality ensures that each hinge meets strict standards for strength, durability, and corrosion resistance. Whether you need a hinge for a garden gate, stable door, or storage shed, TDC provides reliable solutions that stand up to daily use and harsh weather.

Installation Guide

Tools Needed

Before you start, gather the right tools for a smooth installation. You will need:

● Drill with drill bits

● Screwdriver (manual or electric)

● Screws or fasteners (preferably weather-resistant)

● Measuring tape

● Pencil or marker for marking

● Level

● Safety glasses and gloves

Some heavy-duty hinges, especially weld-on types, may require welding equipment. Most standard heavy duty t hinge kits include the necessary screws, but always check if you need sturdier fasteners for outdoor gates.

Preparation

Start by measuring your gate and post to ensure proper alignment. Hold the hinge in place and use a pencil to mark the screw holes on both the gate and the post. Dry-fitting the hinge helps you see how it will move and lets you make adjustments before drilling. Use a level to check that the hinge sits straight. This step prevents sagging and ensures smooth operation.

Installation Steps

Follow these steps for a secure and lasting installation:

1. Position the shorter horizontal part of the hinge on the fixed post or frame.

2. Mark the screw locations using your pencil.

3. Drill pilot holes at each mark to prevent the wood or metal from splitting.

4. Attach the hinge to the post using screws. Tighten them securely.

5. Align the longer strap of the hinge with the gate. Mark and drill pilot holes.

6. Secure the hinge to the gate with screws.

7. Check the swing of the gate. Adjust as needed for smooth movement.

For best results, add a diagonal support brace to your gate. This brace helps distribute weight and prevents sagging, especially for wide or heavy gates.

Mistakes to Avoid

Avoid these common errors to keep your gate stable and secure:

1. Skipping pilot holes can cause wood to split or screws to loosen.

2. Using the wrong size hinge or fasteners may lead to sagging or failure.

3. Ignoring the need for diagonal bracing can result in a drooping gate.

4. Failing to use corrosion-resistant screws or hinges can cause rust and weaken the installation.

5. Not checking for level alignment may cause the gate to bind or drag.

Note: Regular inspection and maintenance help prevent long-term issues and keep your gate working smoothly.

Maintenance Tips

Cleaning and Lubrication

Keeping your hinges clean and well-lubricated helps your gate work smoothly year after year. You do not need complicated tools or expensive products. Most of the time, you can use a soft cloth and a mild cleaner to wipe away dirt and debris. For best results, follow these simple routines:

● Wipe the hinge surfaces with a damp cloth every few months to remove dust and grime.

● Apply a small amount of lubricant, such as silicone spray or light machine oil, to the moving parts. This reduces friction and prevents squeaking.

● Check for signs of rust, especially after heavy rain or snow. If you see any, clean the area and apply a rust-resistant spray.

● Keep a service log to track when you last cleaned and lubricated your hinges.

You will find that a heavy duty t hinge with a quality finish, like galvanization or anodizing, needs very little upkeep. These finishes protect against rust and wear, so you spend less time on maintenance and more time enjoying your gate.

Inspection and Adjustment

Routine inspections help you catch small problems before they turn into big repairs. You should check your hinges at least twice a year, or more often if your gate gets heavy use or faces harsh weather. Use this checklist to guide your inspection:

● Look for loose screws or fasteners and tighten them if needed.

● Test the gate’s movement. It should swing freely without sticking or dragging.

● Inspect the hinge pins and straps for signs of wear or bending.

● Replace any worn or damaged parts right away to avoid further issues.

● Lubricate the hinges during each inspection to keep them moving smoothly.

If you notice your gate sagging or not closing properly, adjust the hinges or add a support brace. High-quality hinges, like those found on a heavy duty t hinge, often require only minor adjustments over time. By following a regular maintenance schedule, you help your gate hardware last longer and perform better.Upgrading your gate with a heavy duty t hinge gives you strength, security, and lasting performance. You get reliable results when you choose quality products like TDC Hinges and select the right finish for your environment. Follow this guide to make your gate upgrade simple and effective. If you need a different solution, explore the full range of external hinges to find the best fit for your project.

FAQ

How do I know what size T hinge I need?

Measure your gate’s width and weight. Check the manufacturer’s recommendations for hinge size and load rating. Choose a hinge that supports your gate’s weight and fits its dimensions. Using the right size prevents sagging and ensures smooth operation.

Can I use heavy duty T hinges for metal gates?

Yes, you can use heavy duty T hinges for metal gates. Select hinges made from strong materials like galvanized steel or stainless steel. Make sure you use the correct fasteners for metal surfaces to ensure a secure fit.

How often should I lubricate my T hinges?

Lubricate your T hinges every three to six months. If your gate faces harsh weather or heavy use, check and lubricate more often. Regular lubrication keeps the hinges moving smoothly and prevents squeaking.

What finish is best for outdoor gates?

Finish Type | Benefits |

Galvanized | High rust resistance |

Anodized | Extra wear and corrosion proof |

Stainless Steel | Durable and weather resistant |

Choose a finish that matches your climate for the best protection.

Do I need special tools to install heavy duty T hinges?

Most installations require basic tools like a drill, screwdriver, level, and measuring tape. For weld-on hinges, you need welding equipment. Always check the hinge instructions before starting your project.

If you need further consultation and discussion, please feel free to contact us.

Email: kathy@tdc-hardware.com

WhatsApp / Cell: +8613325838282

To Provide You with Better Service

Contact

Tel: +8613325838282

Add: 6265 Providence Way Eastvale,CA 92880