How to Choose Commercial Door Hinges

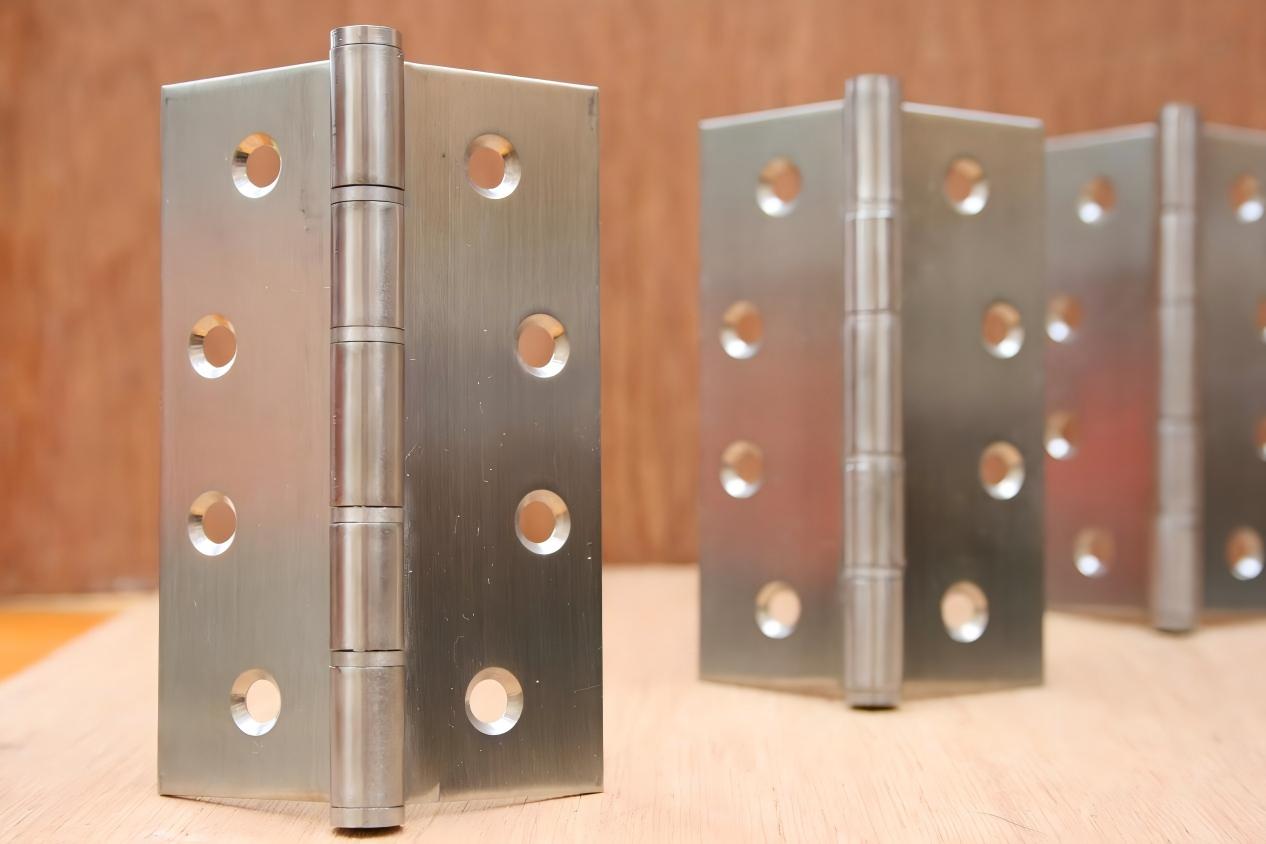

Commercial door hinges are engineered differently from standard residential hinges. They use thicker materials, heavier gauges, and often include ball bearings or springs to endure constant use. At TDC Hardware, our commercial hinges are built to perform in high-traffic areas like offices, schools, and public facilities with a focus on strength, smooth operation, and long-term durability. Commercial hinges typically have thicker steel plates, robust pins, and reliable finishes compare to household door hinges.

Types of commercial hinges

The table below compares the major hinge types often used in commercial settings:

Hinge Type | Description & Use | Pros | Cons |

Ball-Bearing Butt | Heavy-duty butt hinge with steel ball bearings between knuckles. Supports very heavy doors (up to ~1–2 inches thick) and ensures a smooth, quiet motion. Common in hotels, schools and hospitals. | Extremely durable; smooth action; tolerates frequent use. | More expensive; heavier than plain hinges. |

Plain Butt | Standard two-leaf hinge (full or half mortise). Simpler construction (no bearings). Suitable for medium-duty doors. | Easy to install and widely available; good for moderate use. | Less durable under continuous heavy use; may squeak or wear faster. |

Continuous (Piano) | Long hinge that spans the full height of the door. Weight is distributed evenly along the length, minimizing sag. Often used on metal frames or very heavy or long doors. | Superior weight support; ideal for constant-use doors; prevents warping or sagging. | Difficult to install; costlier; requires full-length mortising. |

Pivot | Hinges mounted at the top and bottom of the door rather than the sides. Door pivots on pins at the floor/ceiling. Common for very heavy doors (e.g. glass storefronts) or where no frame is available. | Supports extremely heavy doors; hidden hardware for a sleek appearance. | Complex installation; needs precise alignment and pivot housings. |

Concealed (Euro) | Sits inside a mortise and is invisible when the door is closed. Offers a clean, modern look. Used in upscale offices or cleanroom doors where aesthetics and security (no visible pins) matter. | Aesthetic appeal; adjustable for precise alignment; suited for heavy doors. | More expensive; complicated to install; limited weight capacity compared to ball-bearing butt hinges. |

Spring hinge (Self-Closing) | Butt hinge equipped with a built-in spring to automatically close the door. Required on many fire and security doors. | Ensures doors always close (useful for exterior or security doors); eliminates need for a separate door closer. | Spring tension must be adjusted for weight; periodic maintenance; not needed for all applications. |

Each hinge type above is designed for different uses. For instance, ball-bearing butt hinges are widely applied in the workhorse of commercial construction – extra-thick leaves (often 4.5×4.5 inches) with internal bearings ensure longevity even under heavy load.

While piano hinges are excellent for very heavy or high-use doors (like dormitory or restroom doors) because they spread the door’s weight across the entire height.

Pivot hinges allow large glass or architectural doors to function smoothly without heavy frame loading.

And spring hinges (self-closing hinges) are used for many fire-rated and exterior doors: they automatically return the door to the closed position for security or energy savings.

What to consider while choosing hinges for a commercial door

When choosing hinges for a commercial door, several factors should guide your decision:

Door Weight & Size:

Start by assessing the door’s weight, height, and thickness. Heavier or taller doors demand more robust hinges (thicker gauge steel and larger pin diameters).

For example, a thick iron-clad door may require a Grade 1 (ANSI A156.1) hinge in 4″×4″ or 4.5″×4.5″ dimensions.

A typical entry door (35″×80″) might use 3 hinges of 4″ size; a heavier steel door may need 4 hinges or 4.5″ sizes.

TDC’s heavy-duty stainless steel hinges often use 2.2 mm (0.086″) steel or thicker. This extra thickness prevents bending under load.

If you have a door that is quite large and wide, then you should pick a hinge that is 5” or more, rather than trying to make smaller hinges work with a heavy door.

Frequency of Use:

Consider how often the door opens and closes. In a high-traffic environment (shopping mall, hospital corridor, airport), ball-bearing or continuous hinges are preferable.

These designs minimize friction and resist wear over millions of cycles. In low-traffic settings (storage rooms, infrequently used offices), a standard plain-bearing butt hinge may suffice. Always match hinge durability to usage: commercial hinges are typically rated by ANSI/BHMA grades, with Grade 1 for the most rigorous use.

Environment:

Indoor climate and outdoor exposure have great effect on material choices.

For outdoor areas, use stainless steel or brass hinges (often 304 or 316 stainless) to resist rust. TDCHINGES recommends stainless for extreme weather due to durability and resistance to rust.

For indoor doors, galvanized or powder-coated steel hinges can work if corrosion is not a concern. Also consider any special environment: laboratory or food-service doors may need electro-polished stainless or even antimicrobial coatings.

Security Requirements:

Fire-rated or secure doors often require special hinges. Some applications demand non-removable pins (security hinges) to prevent door tampering. Fire doors typically use hinges that meet UL standards and ANSI fire-door specs. For instance, self-closing spring hinges are frequently mandated on fire doors, and must comply with Grade 1 fire-rated standards.

Aesthetics & Finish: In public or decorative settings, the look of the hinge matters. Options like brushed stainless, oil-rubbed bronze, or matte black finishes can blend with architecture.

> Increase profitability and quality by upgrading your anodizing process with us.

Concealed European hinges or decorative butt hinges may be chosen purely for appearance. Remember that some finishes (e.g. brass, chrome) suit interior lobbies, while others (stainless, black) are better for exterior use. If the door and frame architecture is elegant, concealed hinges give a clean look, as they are hidden when the door is closed.

The surface finishing of furniture hardware determines the aesthetics and life of furniture itself. Those factors are enhanced due to high corrosion and wear resistance.However strict quality requirements, product reliability and extreme cost pressure threaten its competitive edge in the furniture industries. A process upgrade could be crucial to you business’s profitability.

Installation & Maintenance:

Standard full-mortise butt hinges are simple to mortise and screw in, but pivot and continuous hinges require precise alignment and more complex installation. For very heavy doors, professional installation is often advisable to ensure proper alignment and to avoid crippling the frame.

TDC’s bulk packaging and factory-direct support can help installers get the right parts quickly.

Specialty Uses:

TDC’s lift-off hinges as easy removal without tools, perfect for removable doors and panels. Spring (self-closing) hinges have an integral spring, suit perfectly for a separate door closer. These are common on exterior entrances or in facilities where doors must auto-close for security.

Related Products

stainless steel 4.5″×4.5″ ball-bearing hinge (model CH454534BB) for commercial doors.

This heavy-duty hinge has a thick leaf and internal bearings, ensuring smooth operation on heavy doors.

4″ matte black full-mortise hinge (model RH404022-US19)

This model is specified with 2.2 mm iron steel and removable pin. It is built to last and suitable for external or large interior doors.

Furthermore, we offer bulk and OEM support for distributors, making it easier to source custom hinges in volume. When ordering, distributors should verify model numbers, finish options (e.g. satin nickel, oil-rubbed bronze, black), and any special features (non-removable pins, spring tension tools). It’s often helpful to request samples or quotes, especially for unusual sizes or configurations.

Choosing the right commercial hinges

Choosing the right commercial hinge involves matching hinge type, size, material, and features to the door’s needs.

1. Know the door’s weight and usage, pick a hinge type built for that load.

2. Ensure corrosion resistance for the environment, and meet any code requirements for fire or security.

By consulting our manufacturing experts and comparing hinge specifications, distributors and building managers can ensure the door hardware will perform reliably for years.

Remember that a high-quality commercial hinge is an investment in safety and longevity.

If you need further consultation and discussion, please feel free to contact us.

Email: kathy@tdc-hardware.com

WhatsApp / Cell: +8613325838282

To Provide You with Better Service

Contact

Tel: +8613325838282

Add: 6265 Providence Way Eastvale,CA 92880