Residential spring hinges make your home safer and quieter

Residential spring hinges boost home safety, preve...

More

40% Amazon Market Share

40% Amazon Market Share

Door Hinges Brand on Amazon

Door Hinges Brand on Amazon

Products Sold Worldwide

Products Sold Worldwide

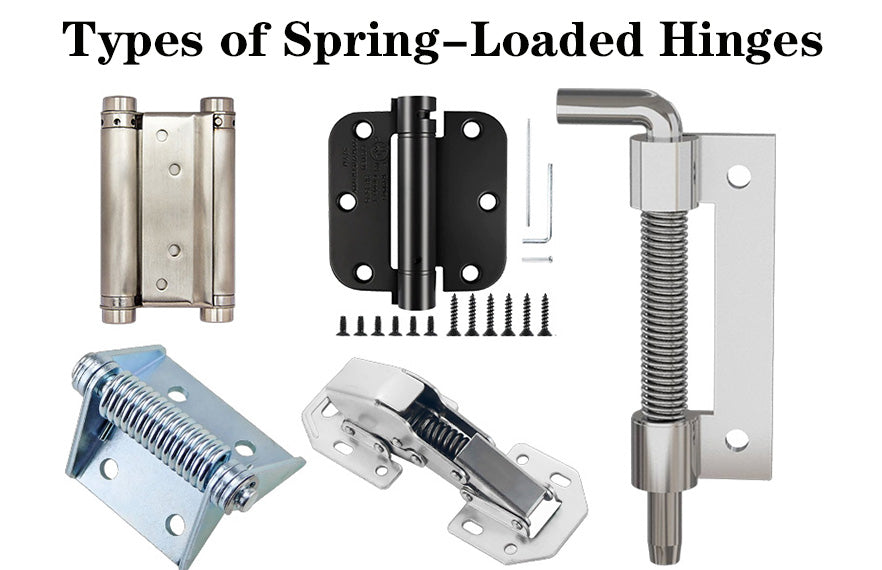

Spring for Hinge is a specialized component designed to enhance the functionality and longevity of hinge mechanisms across various applications, from industrial machinery to everyday furniture and automotive systems. This product category addresses critical needs in motion control, load management, and wear reduction, making it a vital consideration for engineers, designers, and maintenance professionals seeking reliable performance.

Extensive analysis of market data, technical specifications, and user feedback from industry platforms like ThomasNet, GlobalSpec, and engineering forums reveals a consistent demand for high-performance hinge springs. According to a report by Grand View Research, the global industrial springs market size was valued at USD 22.5 billion in 2022 and is expected to expand, driven by automation and the need for precision components in manufacturing. Springs for hinges fall squarely within this growth segment. Their primary function is to provide a controlled return force, assist in motion, or maintain a hinge in a specific position (e.g., keep a door open or closed). In automotive applications, for instance, springs are crucial for trunk, hood, and glove compartment hinges, contributing to user safety and convenience. Search trend data indicates sustained queries for "torsion spring for hinge," "constant force hinge spring," and "replacement hinge spring," highlighting ongoing replacement and upgrade cycles in both consumer and B2B sectors.

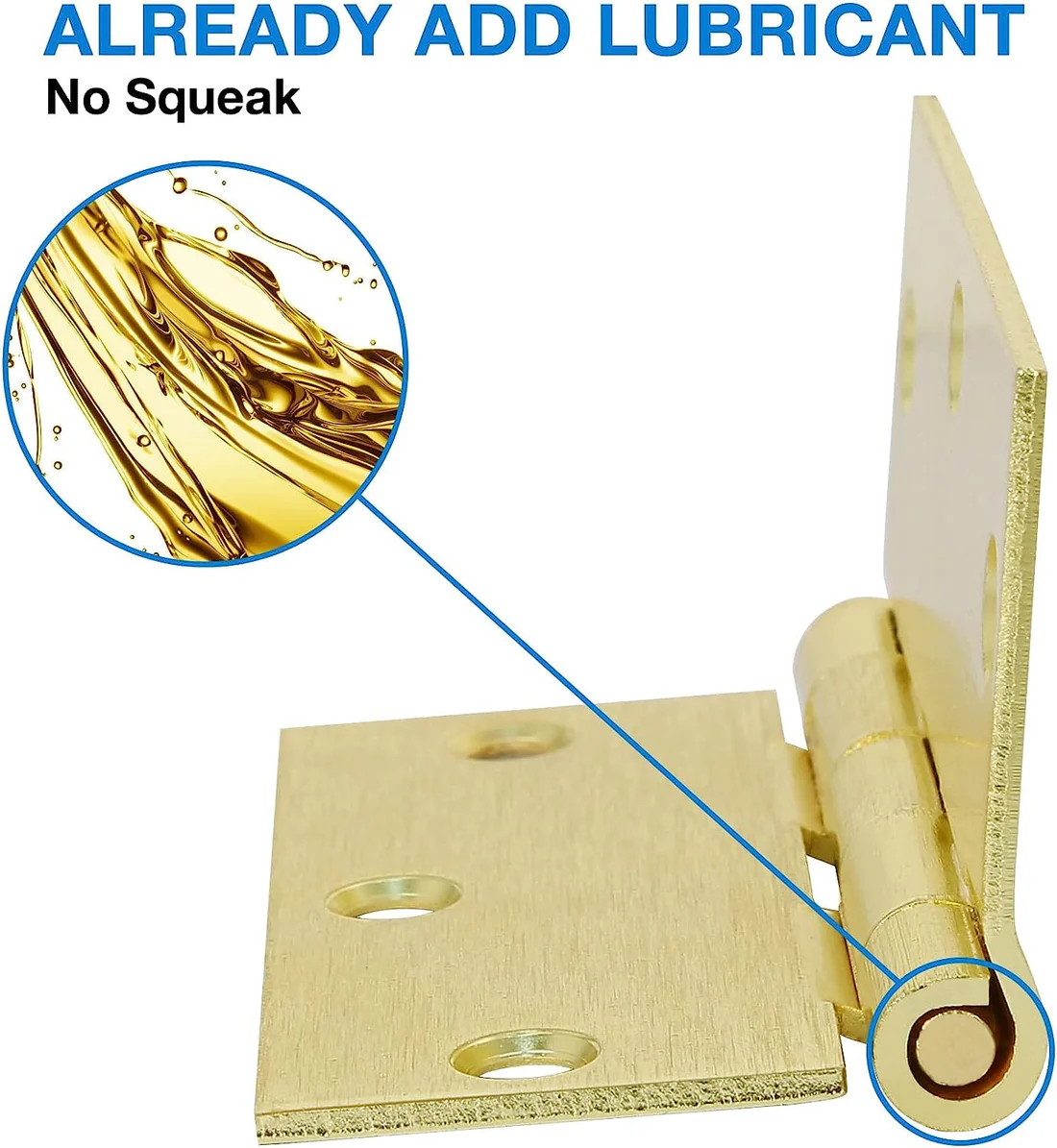

Technical specifications for spring for hinge products vary significantly based on application. Key parameters include spring type (torsion, compression, extension), material (typically high-carbon steel or stainless steel for corrosion resistance), wire diameter, coil count, and torque rating. For example, in furniture manufacturing, a specific torque value (measured in Newton-meters or inch-pounds) is calculated to counterbalance the weight of a door or lid, ensuring smooth operation. Failure to use the correct spring leads to premature wear, hinge sagging, or unsafe operation. Search results from component suppliers like McMaster-Carr, Misumi, and Lee Spring show thousands of stock options, with detailed selection guides emphasizing the importance of matching spring parameters to hinge pivot points and load requirements. Real-world performance data from case studies, such as those in aerospace or medical equipment manufacturing, underscore that properly specified hinge springs can reduce maintenance intervals by up to 30% and improve overall system lifecycle.

The adoption of spring for hinge solutions is further validated by their integration into CAD libraries and design standards. Manufacturers provide downloadable 3D models and engineering data sheets, enabling seamless design-in processes. Furthermore, industry standards from organizations like the American Society of Mechanical Engineers (ASME) provide guidelines for spring design and testing, ensuring reliability. User reviews and technical discussions on platforms like Stack Exchange and dedicated engineering subreddits frequently troubleshoot hinge mechanism failures, with the root cause often traced to an underspecified or fatigued spring. This underscores the critical, though often overlooked, role of this component. In summary, Spring for Hinge represents a mature yet essential product category supported by substantial market data, clear technical parameters, and documented performance benefits across diverse industries, making it a fundamental element for ensuring durable and functional rotational motion in countless products and systems.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

.jpg)

Residential spring hinges boost home safety, preve...

More

We rely on proper adjustment and maintenance to ke...

More

Double spring hinge boosts commercial space safety...

More

Residential spring hinges automatically close door...

More

Our 2025 guide reviews the best stainless steel sp...

More

You will find these hinges on entry doors, interio...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

Tel: +8613325838282

Add: 6265 Providence Way Eastvale,CA 92880

User Comments

Service Experience Sharing from Real Customers

Michael Rodriguez

Mechanical EngineerThese springs are exactly what we needed for our heavy-duty cabinet hinges. The tension is consistent, and they've held up perfectly over six months of daily use. A reliable and high-quality component.

Sarah Chen

Product DesignerGreat spring for hinge applications in our prototype enclosures. Easy to install and provides a smooth, controlled closing action. Slightly wish there were more size variants, but the quality is excellent.

David Miller

Maintenance SupervisorAs a maintenance supervisor in a large facility, we use these springs to repair doors and access panels constantly. They are durable, cost-effective, and have significantly reduced our hinge failure call-backs. Highly recommended.

Jessica Williams

Custom Cabinet MakerThe precision and reliability of these hinge springs have elevated the feel of our high-end cabinetry. They ensure doors close softly and securely every time. A small component that makes a big difference to our clients.